We cooperate with ISABER to develop 4-6 inch InP-Si and InP-SiO2/Si wafers. The wafers use surface activated bonding technology to bond thermal oxide wafers and Indium Phosphide wafers together, and then control the thickness to the thickness you need through ion implantation, annealing, thinning or direct thinning and CMP polishing. It is worth noting that ion implantation and direct CMP and thinning have their own advantages and disadvantages.

Bonding modification layer

Different from conventional hydrophilic bonding, we use Surface Actived Bonding Technology. During bonding, a modified layer is added in the middle to match the upper and lower bonding surfaces. The material of the modified layer is generally amorphous silicon/aluminum oxide/titanium oxide. For optical applications, we recommend aluminum oxide or titanium oxide. Users can choose different intermediate layers according to their needs. This bonding method can effectively avoid bubbles during the bonding process. For mass-produced products, according to our specifications.

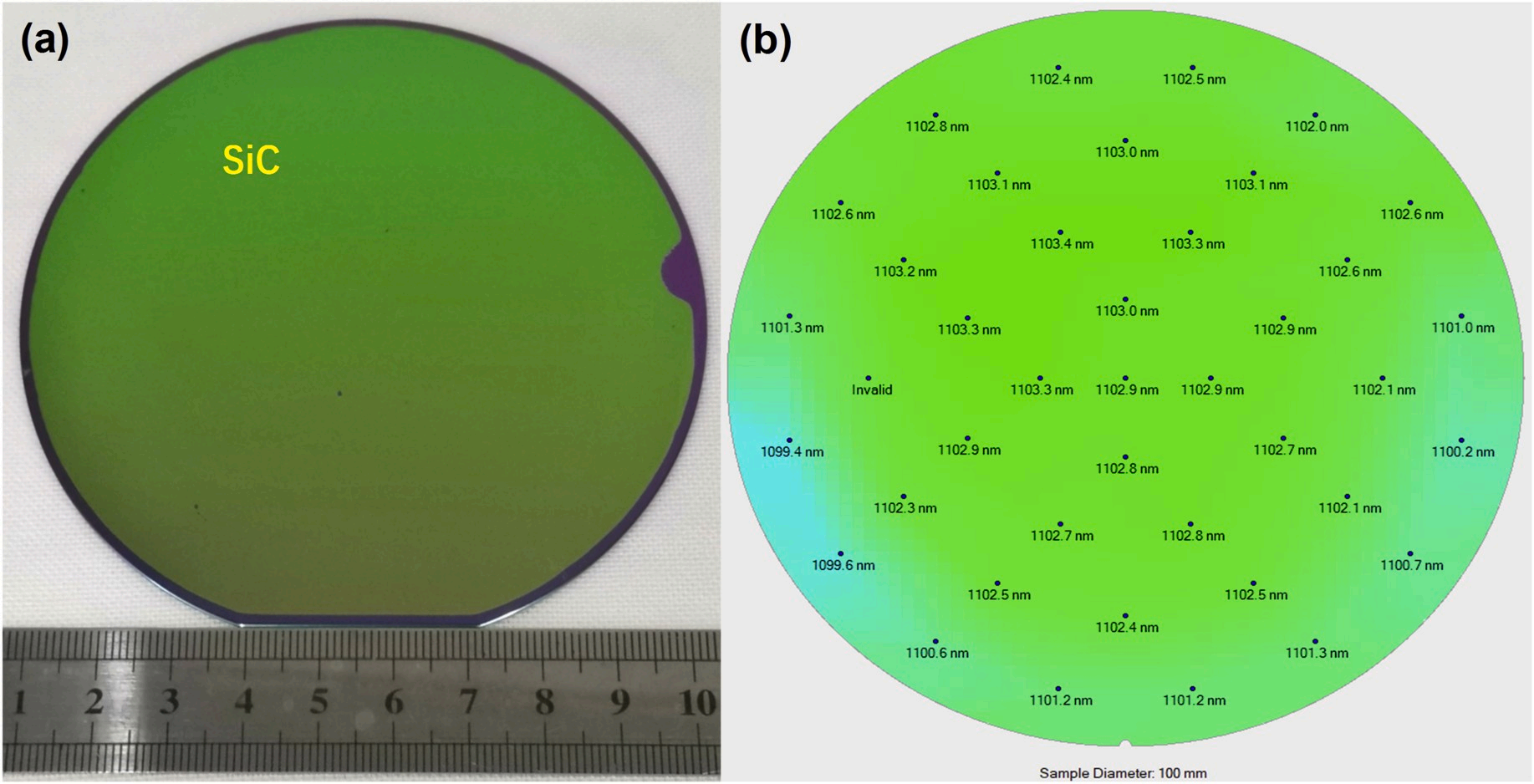

Film thickness range and accuracy

Based on SMARTCUT process

Film thickness range: 150nm-20um

Film thickness uniformity +-20nm

Based on Grinding+CMP process

Film thickness range: 200nm-any thickness

Film thickness uniformity: +-100nm:

SmartCut VS Direct Thining&CMP Polishing

SmartCut Process can provide excellent film thickness accuracy, but the ion implantation process will have a certain impact on the silicon carbide material, which will affect the device performance when used in optical applications.

Direct thinning and CMP polishing will not damage the material properties and can provide good device performance, but this method cannot well control the thickness accuracy of the silicon carbide layer.

Cavity

We also have deep etching technology to process grooves with a certain spacing and depth on thermal oxide wafers or silicon wafers. These grooves can help release the stress during epitaxial growth and avoid separation or fragmentation of the film layer.

OMedaSemi can provide InPOI wafer based on both Smartcut and thinning and polishing processes.

Application:

InP-Si HBT

See related article :

Laser on Chip

See related article :

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.