OMedaSemi provide Two Photon 3D Printing Service,we use Nanoscribe Phtonics GT2 Pro & Nanoscribe Quantum X and Nanoscribe IP Dip Glue to print nanostructure on most of substrate .

Processing Capabilities:

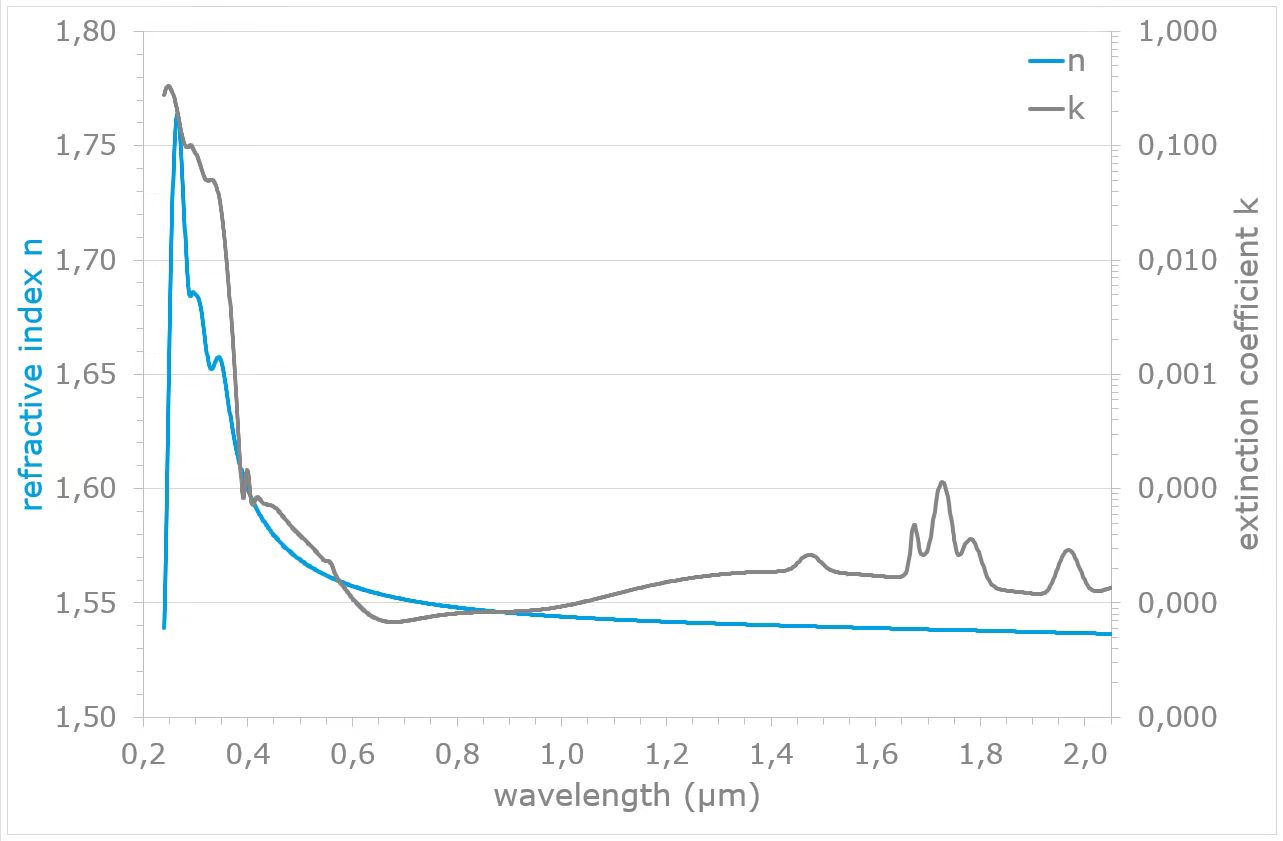

●Refractive index of photoresist: 1.56

Refraction Index of Ip Dip Glue(if you print lens or other optical structure,you can use this data to do simulation),this data is cited from Nanoscribe.com

●Feature size: 200 nm horizontally, 400 nm vertically

●Aspect ratio: 5:1.

●Maximum size: 500um*500um

●Maximum height: 300um

●Substrate: glass/optical fiber/other smooth substrate

●Printing shape: microneedles, microlenses, optical fiber end face structures, diffraction structures, other micro-nano structures

Example that we did:

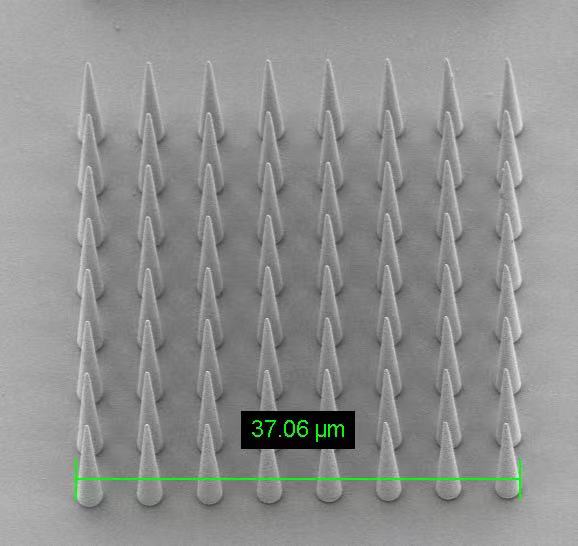

Micro Needle

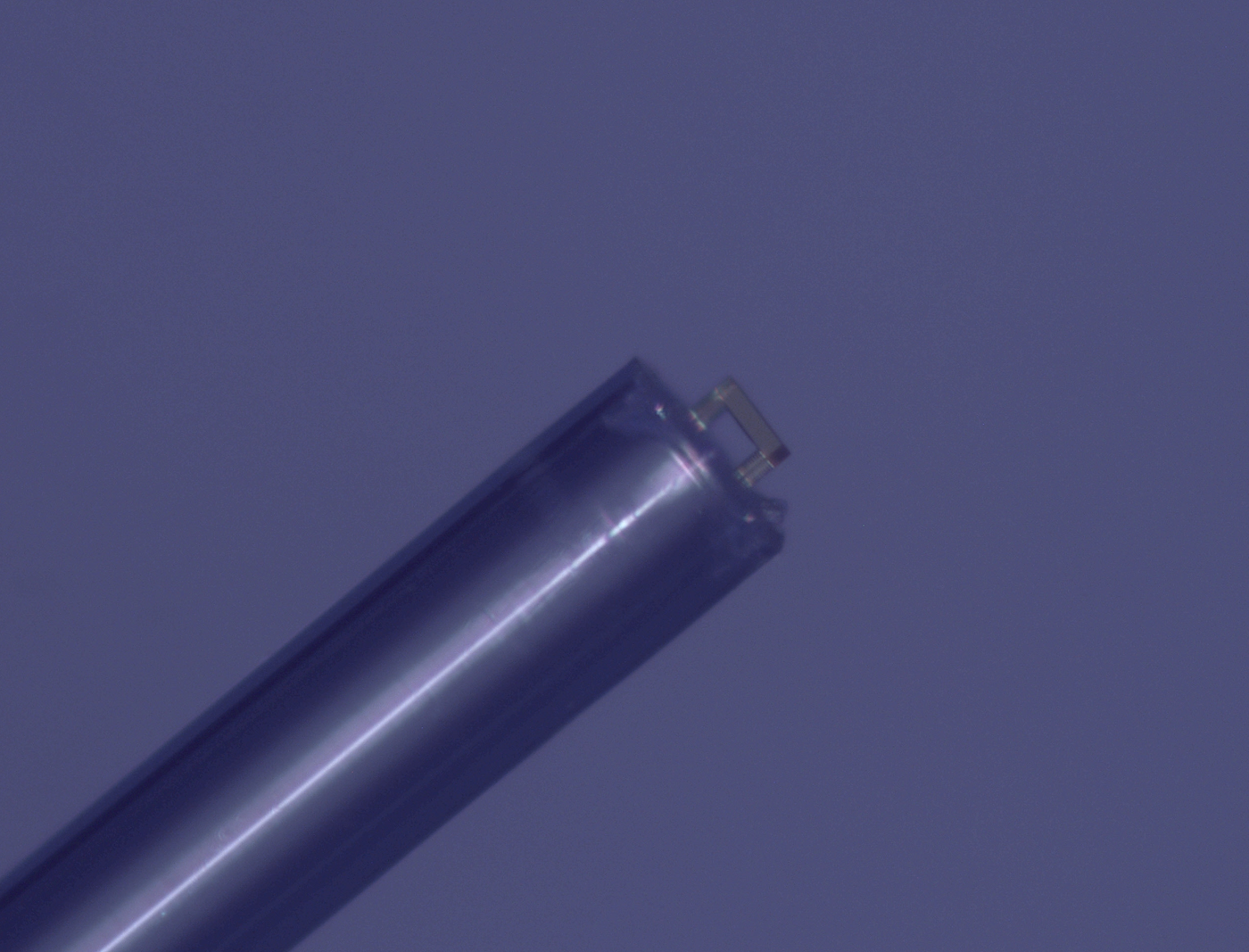

Micro structure on Fiber Tip

Principle:

Two-photon 3D printing (TPP) is an advanced photolithography technology that uses the two-photon absorption effect to form three-dimensional micro-nano structures in photosensitive materials through high-precision laser focusing. The following is a detailed introduction to the basic principles, process flow, application scenarios, advantages and etching accuracy of two-photon 3D printing:

Two-photon 3D printing uses femtosecond laser (usually near-infrared light) to focus on photosensitive materials and trigger polymerization reactions through the two-photon absorption effect:

1. Two-photon absorption: In photosensitive materials, two photons are absorbed by a molecule at the same time, exciting electrons to jump to a higher energy state and trigger chemical reactions.

2. Polymerization reaction: In photosensitive materials, the excited molecules trigger monomer polymerization reactions to form solid polymers.

3. High resolution: Since two-photon absorption only occurs at the laser focus, the energy is concentrated in a very small volume, which can form high-resolution three-dimensional structures.

Equipment introduction:

●Brand: Nanoscribe

●Series: Photonics Pro GT2

●Minimum XY feature size: typical 160 nm; specified 200 nm*

●Most accurate XY resolution: typical 400 nm; specified 500 nm*

●Most accurate vertical resolution: typical 1,000 nm; specified 1,500 nm*

Process flow:

1. Photosensitive material preparation: Select and prepare appropriate photosensitive materials, such as photosensitive resins, and coat or fill them on the substrate.

2. Laser focusing: The femtosecond laser is focused to a specific position inside the photosensitive material through the microscope objective.

3. Pattern design: The three-dimensional motion platform is controlled by a computer, and the laser focus is moved according to the predetermined pattern, and the exposure is scanned layer by layer.

4. Polymerization reaction: The material at the laser focus undergoes polymerization reaction to form a solid structure.

5. Removal of unreacted materials: After the exposure is completed, the unpolymerized photosensitive material is washed away, and only the solidified three-dimensional structure is retained.

Application:

Two-photon 3D printing is widely used in the following fields:

Microelectromechanical systems (MEMS): used to make high-precision microstructures and microdevices.

Biomedical engineering: such as the production of tissue engineering scaffolds, microfluidic chips and bionic structures.

Photonics: such as the production of photonic crystals, optical devices and waveguides.

Materials science: used to study new materials and nanostructures.

Advantages:

Ultra-high resolution: It can achieve submicron or even nanometer resolution, which is suitable for the production of complex micro-nano structures.

Three-dimensional freedom: Ability to focus at any position in three-dimensional space to produce complex three-dimensional structures.

Material diversity: Applicable to a variety of photosensitive materials, including organic and inorganic materials.

Non-contact processing: No physical mask or mold is required, reducing damage and contamination during processing.

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.