Principle:

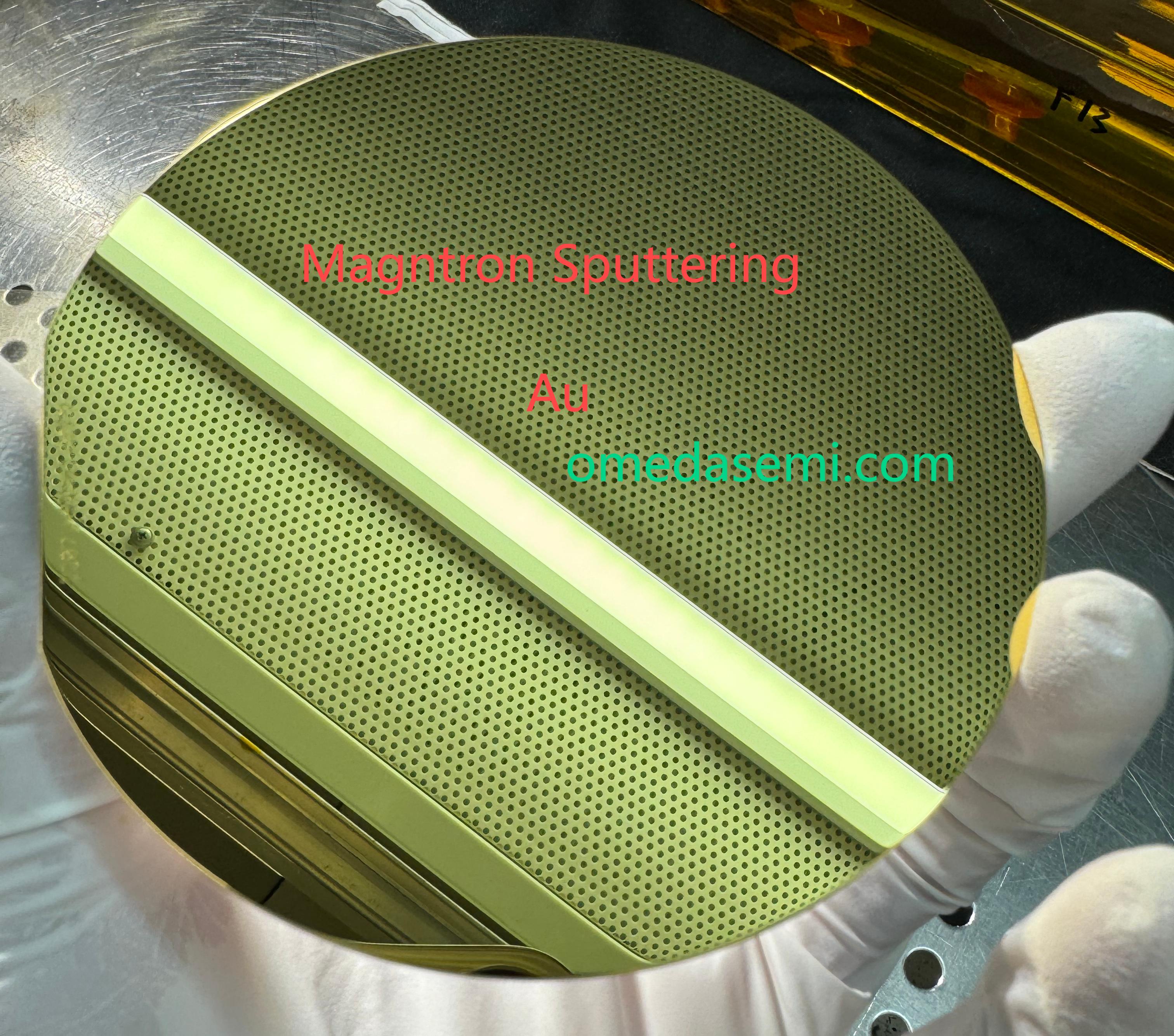

Sputtering deposition is well suited for high melting point materials that cannot be evaporated. Magnetron sputtering is a versatile method for creating dense thin films with good adhesion. Magnetron sputtering is a plasma-based coating method that creates a magnetically confined plasma near the target surface. Positively charged energetic ions from the plasma then collide with the negatively charged target material and atoms from the target are ejected or "sputtered" and then deposited on a substrate or wafer.

Processing Capabilities:

Metal films: Au, Ag, Ta, Al, Cu, Fe, Mo, Ti, Ni, W, Ge, Ir, Cr, Co

Oxide films: Ta2O5, TiO2, GaO, Ga2O3, Al2O3, IZO, IGZO, ITO, CeO, HfO2, NiO, ZrO2, Y2O3, WO3, MgO

Other materials: GaN, AlScN, AlN, TiN, SiNX, Si3N4, SiC, SiON, Poly Si, α Si, InP

Substrate: ceramic, sapphire, diamond, gallium nitride, silicon carbide, polyimide Pi ,Pet film

Advantages:

Our magnetron sputtering coating equipment has a variety of models

a. 4-12 inch single-piece equipment

b. 4-12 inch continuous coating equipment

c. 6-inch magnetron sputtering coating equipment with 6 pieces per furnace

d. 6-inch/8-inch magnetron sputtering coating equipment with 12 pieces per furnace

Application: optical coating, semiconductor coating

Supported size: 4-12 inches, up to 600mm

Advantages:

Excellent film thickness accuracy and film coating density - achieve denser coatings than evaporation

Ideal for metal or insulating coatings with specific optical or electrical properties

Multiple magnetron sources can be configured

Know More about our Coating Capbility

| Material | EBE | magnetron Sputtering | IBS | PECVD | ICPCVD | LPCVD | ALD | PLD | MOCVD | MBE |

| Au | O | O | ||||||||

| Ag | O | O | ||||||||

| Ta | O | |||||||||

| Al | O | O | ||||||||

| Cu | O | |||||||||

| Fe | O | |||||||||

| Mo | O | |||||||||

| Ti | O | O | ||||||||

| Ni | O | O | ||||||||

| W | O | |||||||||

| Ge | O | |||||||||

| Ir | O | |||||||||

| Zr | O | |||||||||

| Pt | O | O | ||||||||

| Cr | O | O | ||||||||

| NiCr | O | |||||||||

| TiW | O | |||||||||

| WC | O | |||||||||

| C | O | |||||||||

| NiSn | O | |||||||||

| AgSn | O | |||||||||

| AuSn | O | O | ||||||||

| MoS2 | O | |||||||||

| Ta2O5 | O | O | ||||||||

| TiO2 | O | O | O | |||||||

| GaO | O | |||||||||

| Ga2O3 | O | |||||||||

| Al2O3 | O | O | ||||||||

| IZO | O | |||||||||

| IGZO | O | |||||||||

| ITO | O | |||||||||

| CeO | O | |||||||||

| HfO2 | O | O | ||||||||

| NiO | O | |||||||||

| ZrO2 | O | O | O | |||||||

| Y2O3 | O | |||||||||

| WO3 | O | |||||||||

| MgO | O | O | O | |||||||

| GaN | O | |||||||||

| AlScN | O | |||||||||

| AlN | O | |||||||||

| TiN | O | |||||||||

| SiNX | O | O | ||||||||

| Si3N4 | O | O | O | |||||||

| SiC | O | |||||||||

| SiON | O | |||||||||

| Poly Si | O | |||||||||

| α Si | O | O | O | |||||||

| TEOS Sio2 | O | O | ||||||||

| SrTiO3 | O | |||||||||

| BaTiO3 | O | |||||||||

| MgF2 | O |

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.