I am glad that you can see this page.

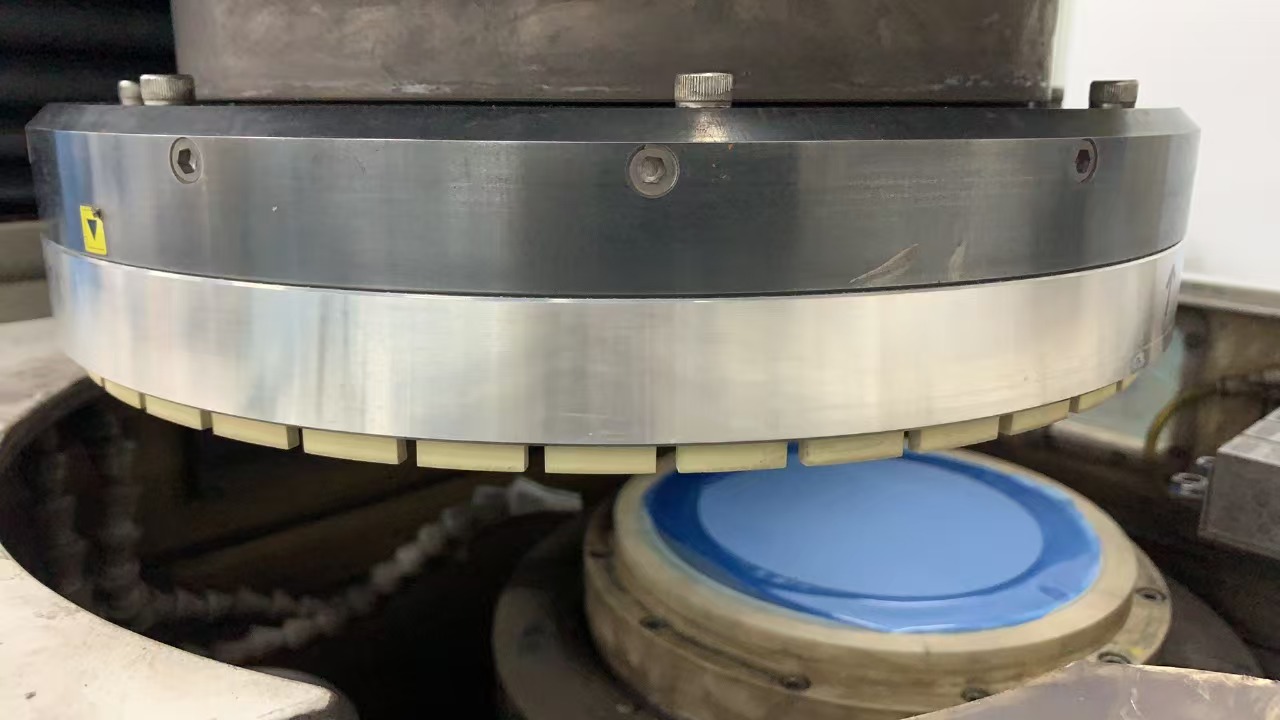

OMedaSemi provides mechanical thinning and chemical mechanical polishing services. In semiconductor processing, mechanical thinning process is widely used. For example, after the cladding growth in photonic integrated circuits, the top cladding needs to be chemically mechanically polished to reduce the roughness of the cladding. In the preparation of thin-film lithium niobate and SOI wafers, the material needs to be thinned and polished before and after the bonding process. In the preparation of wafers, the wafers after wire cutting need to be chemically mechanically polished before the post-processing.

However, the industry lacks professional and reliable suppliers of mechanical thinning and chemical mechanical polishing processing

Grinding thinning:

Materials:

Conventional materials; Si, Glass, Sapphire

Compound semiconductors; InP, GaAs

Crystals; LiTaO3/LiNbO3

Advanced substrates; SiC, GaN, Diamond

Thin films; Si3N4/SiO2

Size: 4 inches, 6 inches, 8 inches

CMP polishing:

Material requirements:

Conventional materials; Si, Glass, Sapphire

Compound semiconductors; InP, GaAs

Crystals; LiTaO3/LiNbO3

Advanced substrates; SiC, GaN, Diamond

Thin films; Si3N4/SiO2

Size: 4 inches, 6 inches, 8 inches

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.

9:00-18:00 Sales Service Hotline

Inquiry, cooperation consultation email

Whatsapp / Phone

+86 188 233 40140