This paper presents a novel fabrication approach for suspended 4H-silicon carbide (4H-SiC) membranes aimed at integrating point defects into quantum devices. 4H-SiC is a promising material for quantum technologies, particularly because of its ability to host spin-active color centers, which are crucial for applications such as single-photon emission, quantum metrology, and secure quantum networks. The challenge in utilizing 4H-SiC has been the difficulty in fabricating suspended thin films due to the material’s mechanical and chemical stability.

Key findings include:

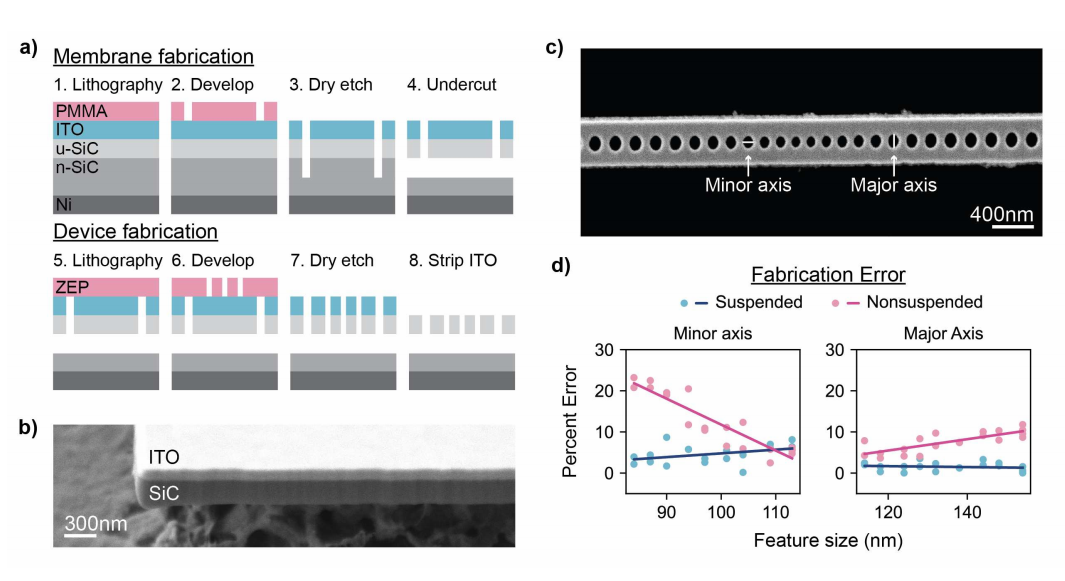

Fabrication Process: A new technique is introduced where suspended thin films of 4H-SiC are first created using a photochemical etching (PEC) method before device patterning. This contrasts with traditional methods where devices are patterned on unsuspended materials and later undercut. The new approach provides several advantages, including reduced proximity effects and improved fabrication precision, particularly for small feature sizes.

Device Demonstration: The technique is used to fabricate 1D photonic crystal (PhC) cavities, which are essential for enhancing zero-phonon line (ZPL) emission through the Purcell effect. These cavities showed quality factors (Q) in the thousands, confirming the potential of the approach for photonic device integration with defects.

Tapered Fiber Coupling: To address inefficient light collection, tapered fiber-coupled cavities were fabricated, improving light extraction and enabling better photon readout. This is a crucial step for quantum applications requiring efficient photon collection.

Integration with Lithium Niobate: A phononic crystal cavity integrating thin-film lithium niobate (TFLN) with 4H-SiC was also demonstrated, paving the way for enhanced spin-state readout through piezoelectric transduction and surface acoustic wave generation. This integration opens up new possibilities for coupling quantum emitters to mechanical devices.

Future Potential: The approach is shown to be highly flexible and robust, capable of withstanding high-temperature fabrication processes due to the monolithic nature of the suspended membranes. This is particularly important for defect activation and other applications that require high-temperature annealing.

In conclusion, the paper introduces a promising fabrication method for 4H-SiC-based quantum devices. The suspended membrane platform enhances fabrication precision, integration flexibility, and device performance, making it an attractive option for future quantum technologies involving spin-active defects.

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.