Wafer Grinding Machine

High-Precision Grinding

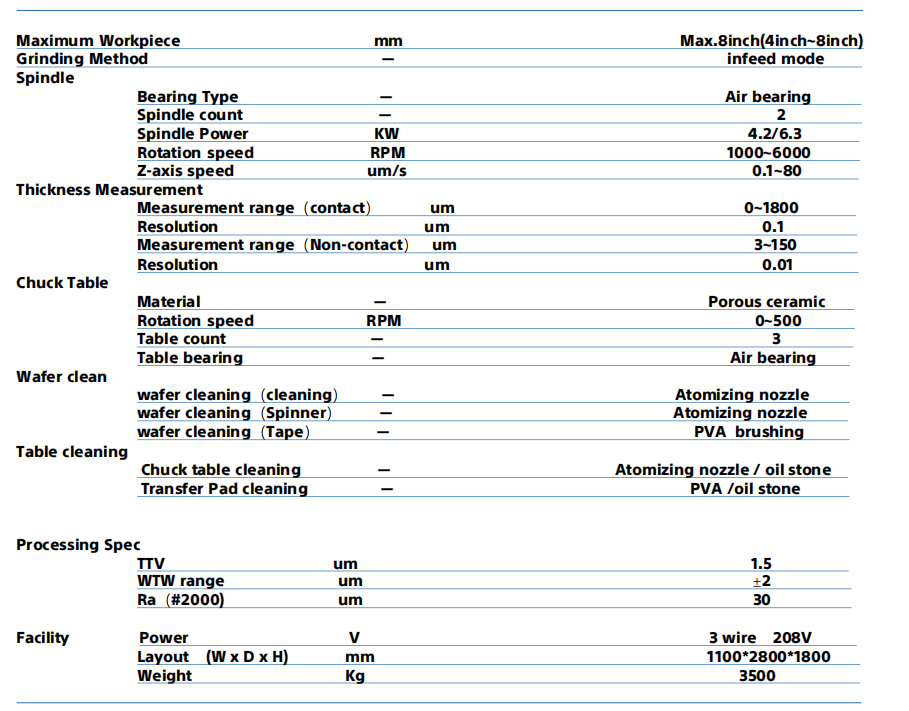

The entire machine is equipped with a spindle axis that has high rigidity, low vibration, and minimal rotational speed fluctuation to achieve high precision and quality processing. For the chuck table axis, an air bearing unit has been installed, which is characterized by high rigidity, low vibration, low thermal expansion, and minimal rotational speed fluctuation.

Available for various wafer

The entire machine is equipped with 2 spindle(6.3kw) axis 3 chuck tables and one turn table. This machine supports various workpieces up to Φ8 inches, including difficult-to-process materials such as Silicon, LT, LN, and SiC.

Usability

The user interface equipped 21 inch display panel. User can monitor the machine`s statue and wafer process data in real time at main screen. The software supports a remote interface, allowing users to remotely monitor equipment and operate the software through the Net.

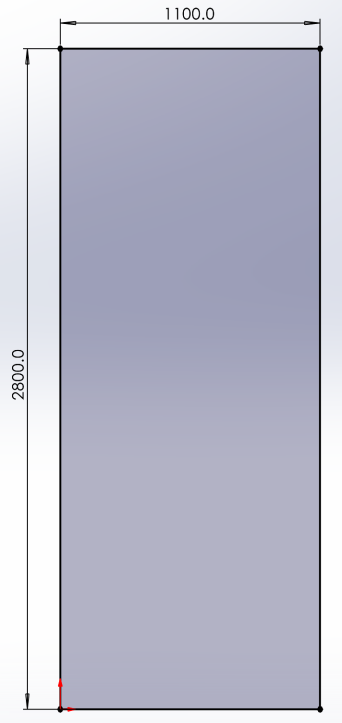

Improved space productivity

The machine's footprint is significantly smaller than that of its industry peers, saving space.

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.

9:00-18:00 Sales Service Hotline

Inquiry, cooperation consultation email

Whatsapp / Phone

+86 188 233 40140