Paper Download

OMedaSemi provide Two Photon 3D Printing Service,we use Nanoscribe Phtonics GT2 Pro & Nanoscribe Quantum X and Nanoscribe IP Dip Glue to print nanostructure on most of substrate(Glass Silicon Fiber) ,you can visit this page to know more : Two Photo Polymerization 3D Printing Service

The article "Two-Photon 3D Printed Spring-Based Fabry–Pérot Cavity Resonator for Acoustic Wave Detection and Imaging" presents a novel approach to fabricating and utilizing optomechanical resonators for acoustic sensing and imaging applications. Here are the key points from the article:

1. **Overview**: The paper proposes a spring-based Fabry–Pérot (FP) cavity resonator designed for highly sensitive acoustic detection and imaging. The resonator is fabricated using a two-photon 3D printing technique directly on an optical fiber tip. This novel approach provides high sensitivity and low noise detection, with potential applications in biomedical imaging and underwater object imaging.

2. **Motivation**: Traditional acoustic sensors based on piezoelectric materials face limitations at high frequencies due to noise and fabrication challenges. Optical fiber-based sensors, especially Fabry–Pérot interferometers (FPIs), offer an alternative with advantages like compact size and immunity to electromagnetic interference. However, their sensitivity can be limited by the stiffness of silica materials used in these systems.

3. **Design and Structure**: The proposed resonator consists of a thin diaphragm supported by flexible springs, allowing greater sensitivity to acoustic waves. The resonance modes of the diaphragm and springs can be tuned by adjusting the structure's dimensions, enabling the detection of weak acoustic signals. The resonator is designed to operate in both low and high-frequency ranges.

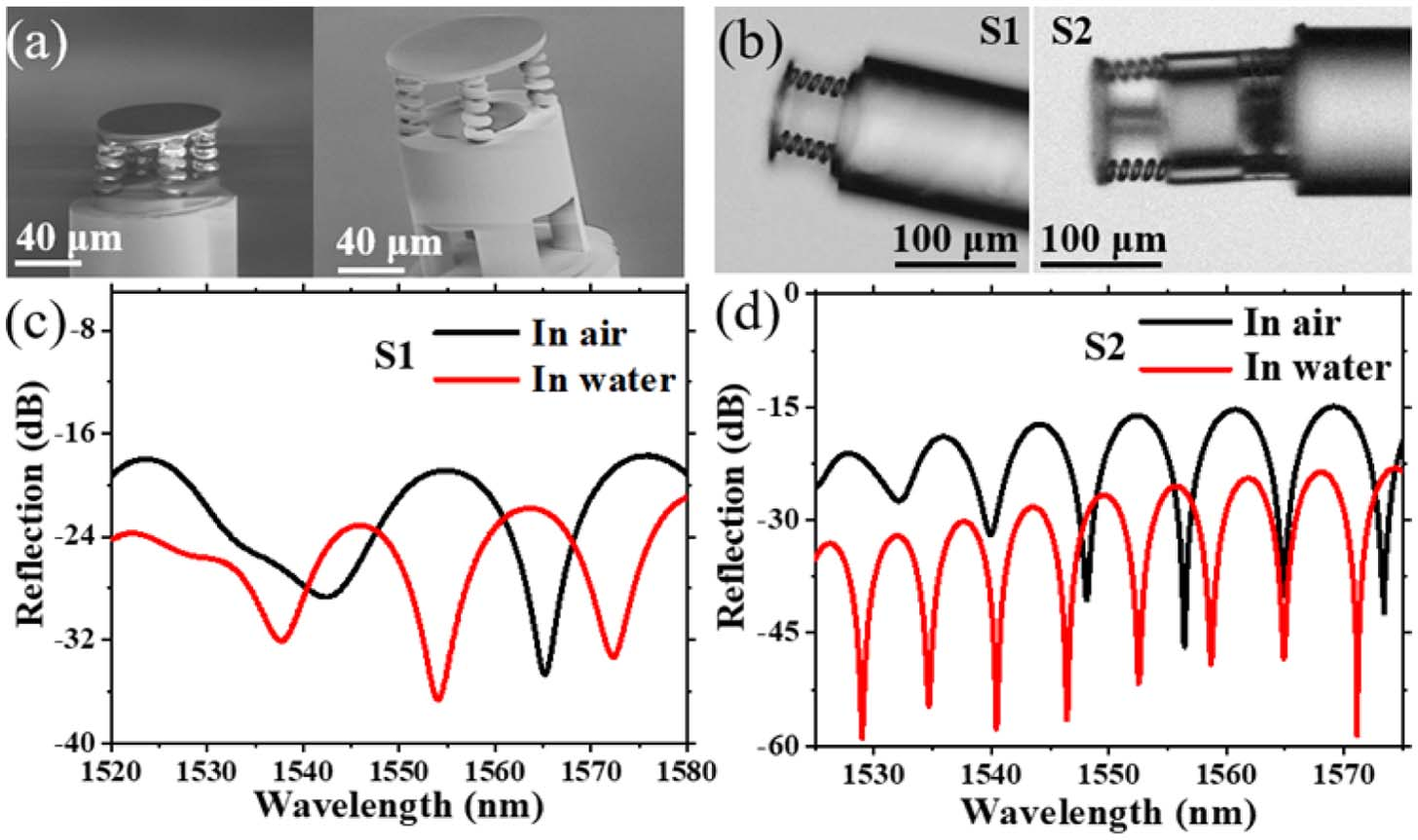

4. **Fabrication Process**: The resonator is fabricated using a two-photon polymerization technique on the tip of an optical fiber. This method enables precise control over the device's structure, allowing the creation of microscale components with smooth surfaces. Two devices with different cavity lengths were produced, and their performance was compared in both air and water environments.

5. **Acoustic Detection Performance**: The device exhibits excellent sensitivity to acoustic waves, with a low noise equivalent acoustic signal level of 2.39 mPa/Hz^(1/2) at 75 kHz. It can detect ultrasonic signals at frequencies up to 750 kHz and demonstrates a linear response to changes in acoustic pressure. Additionally, the device shows a broad angular response, making it suitable for directional acoustic detection in imaging applications.

6. **Applications**: The proposed resonator is particularly promising for underwater imaging, where it can be used to detect and image objects based on the reflection of acoustic waves. The authors demonstrated its capability in an underwater positioning experiment, showing that the device could accurately detect objects and reconstruct their cross-sectional images.

7. **Conclusion and Future Work**: The paper concludes that the spring-based Fabry–Pérot resonator offers significant advantages for acoustic wave detection and imaging, particularly in sensitive environments like biomedical and underwater applications. Future improvements could focus on optimizing fabrication techniques and developing sensor arrays for high-resolution imaging.

In summary, the article introduces a novel 3D-printed acoustic sensor that combines a Fabry–Pérot cavity with flexible springs to enhance sensitivity and performance in detecting acoustic waves, with potential for various high-precision applications.

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.