Paper Download

OMedaSemi provide Two Photon 3D Printing Service,we use Nanoscribe Phtonics GT2 Pro & Nanoscribe Quantum X and Nanoscribe IP Dip Glue to print nanostructure on most of substrate(Glass Silicon Fiber) ,you can visit this page to know more : Two Photo Polymerization 3D Printing Service

The article titled "A methodology for two-photon polymerization micro 3D printing of objects with long overhanging structures" explores a novel approach to address a significant challenge in two-photon polymerization (TPP) 3D printing—printing long overhanging structures without using support materials. Conventional methods struggle with floating and misaligned layers during printing, particularly when objects are larger than the printing field or when overhanging features exceed the size of a single printing block.

Key contributions of the paper include:

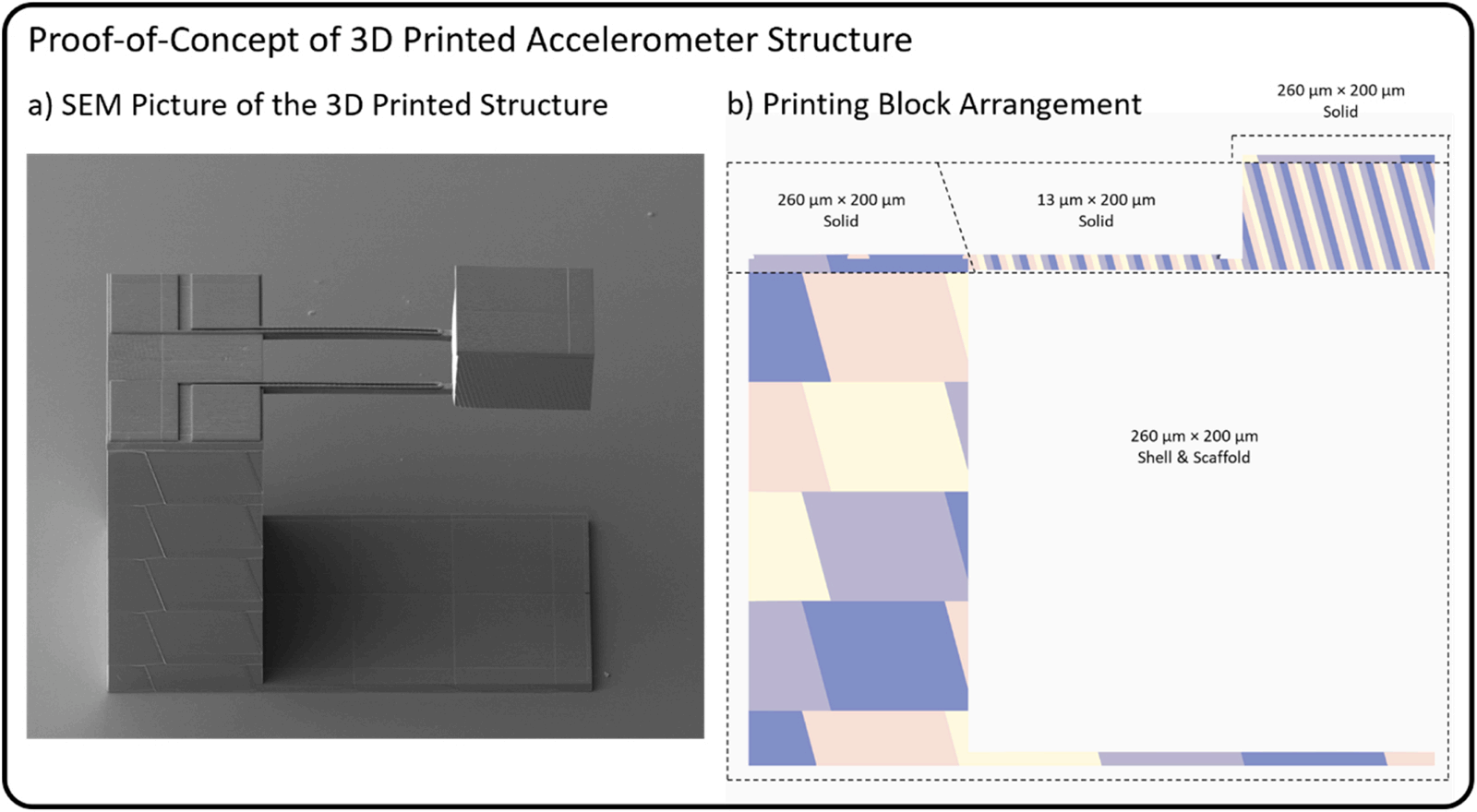

1. **New Printing Methodology**: The authors propose a technique that utilizes small printing blocks and combines Shell & Scaffold and Solid printing modes. This hybrid approach allows for precise layer-by-layer fabrication of long overhanging structures, mitigating issues related to floating layers.

2. **Technical Demonstration**: The methodology was successfully used to print single-sided clamped cantilevers with lengths up to 1000 µm and double-sided clamped beams of similar size. These structures could not be produced by conventional TPP printing techniques. The printed cantilevers demonstrated high structural integrity and consistent dimensions, without requiring post-processing steps like support removal.

3. **Printing Process Optimization**: The authors discuss how block sizes and printing modes can be tailored for different parts of the 3D object, minimizing printing times while maintaining structural quality. This approach significantly extends the application potential of TPP 3D printing for micro- and nano-scale objects, particularly in fields like medicine, photonics, and micro-robotics.

4. **Comparative Results**: The paper highlights how the new methodology outperforms conventional techniques by avoiding distorted or collapsed structures. It provides detailed experimental results and discusses the trade-off between surface quality and printing speed based on block sizes.

Overall, the paper offers a significant advancement in TPP 3D printing technology, enabling more complex designs with long overhanging structures while reducing limitations related to support materials and printing artifacts.

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.