Paper Download

We also have a large stock available. You can visit this page to learn more:https://en.omedasemi.com/detail/134.html

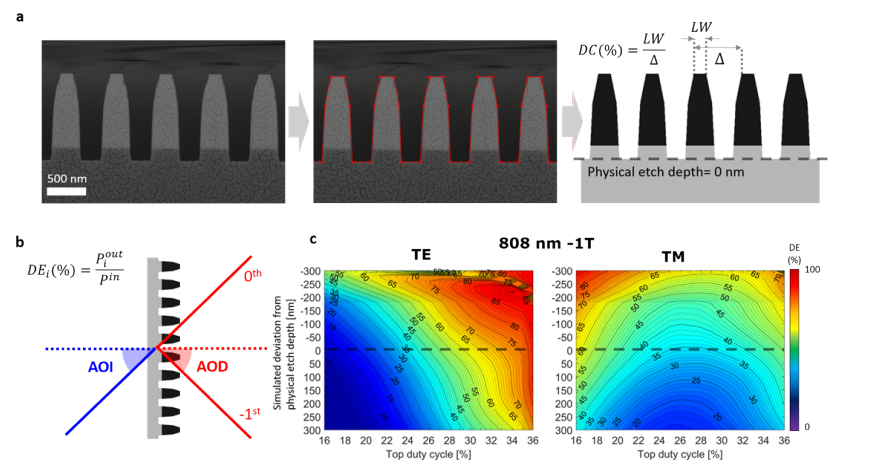

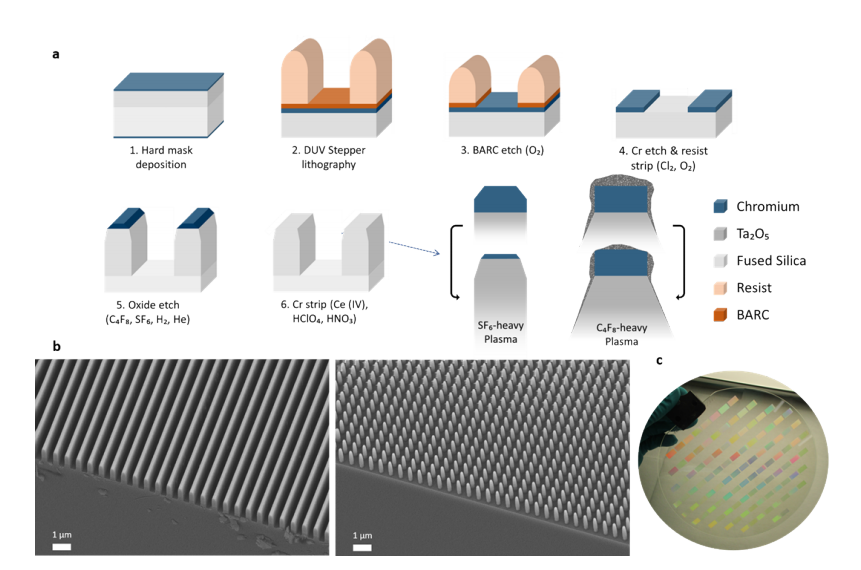

The paper focuses on the fabrication and profile tailoring of high-refractive-index Ta2O5 optical gratings for LiDAR systems, using C4F8/SF6 plasma mixtures. The research investigates how to control the etching process and the resulting grating profiles to achieve high diffraction efficiency (DE), which is crucial for improving LiDAR performance. By adjusting process parameters like power, pressure, and gas ratios during inductively coupled plasma etching, the study optimizes the grating's sidewall angle and duty cycle, leading to efficient diffraction characteristics. The Ta2O5 gratings achieve over 85% DE for both transverse electric (TE) and transverse magnetic (TM) polarizations at 808 nm, making them highly suitable for medium-range LiDAR systems. This work presents a scalable and flexible method for fabricating diffractive optics, applicable to other fields such as augmented and virtual reality, where high-efficiency optical components are essential.

This article details the fabrication and profile tailoring of high-index tantalum pentoxide (Ta₂O₅) optical gratings for applications in light detection and ranging (LiDAR) systems. Ta₂O₅ is highlighted for its high refractive index (RI), low loss in the ultraviolet to near-infrared regions, and suitability for producing efficient diffractive optics. The study focuses on controlling the etching process of Ta₂O₅ using C₄F₈/SF₆ plasma mixtures to create well-defined grating profiles with high diffraction efficiency (DE) for both transverse electric (TE) and transverse magnetic (TM) polarizations.

Key findings include:

The use of a precise inductively coupled plasma-reactive ion etching (ICP-RIE) technique, achieving etch rates of up to 150 nm/min and uniformity greater than 95% across a 150 mm wafer.

Optimization of the plasma etch parameters, specifically adjusting the C₄F₈/SF₆ gas ratio, to control the sidewall angle (SWA) and grating profile, which in turn affects the diffraction efficiency.

The fabrication process results in diffraction efficiencies exceeding 85% for both TE and TM polarizations at a center wavelength of 808 nm, which is suitable for LiDAR applications.

The work also discusses the trade-offs between etch parameters such as power, pressure, and gas flow rates, and their impact on the grating profile and efficiency. The results are validated by comparing the measured diffraction efficiency to simulated values, demonstrating the potential of this method to create highly efficient optical gratings for advanced applications like LiDAR and AR/VR systems.

This research introduces a scalable process for manufacturing high-performance Ta₂O₅-based diffractive optics, paving the way for their widespread use in various optical technologies.

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.