Paper Download

OMedaSemi provide Two Photon 3D Printing Service,we use Nanoscribe Phtonics GT2 Pro & Nanoscribe Quantum X and Nanoscribe IP Dip Glue to print nanostructure on most of substrate(Glass Silicon Fiber) ,you can visit this page to know more : Two Photo Polymerization 3D Printing Service

The article discusses the development of a novel optical fiber microphone based on a 3D-printed microcantilever structure, fabricated using two-photon polymerization (TPP) technology. The goal is to create a highly sensitive microphone that operates efficiently within the human audible frequency range (20 Hz to 20 kHz), achieving a signal-to-noise ratio (SNR) of over 50 dB.

Key Points:

Advantages of Optical Fiber Microphones: Compared to traditional electrical microphones, optical fiber microphones offer better immunity to electromagnetic interference and more compact designs. Microphones using Fabry-Perot Interferometers (FPI) have gained attention for their simple structure and effectiveness in acoustic sensing, though there are challenges related to the stiffness of materials and processing precision.

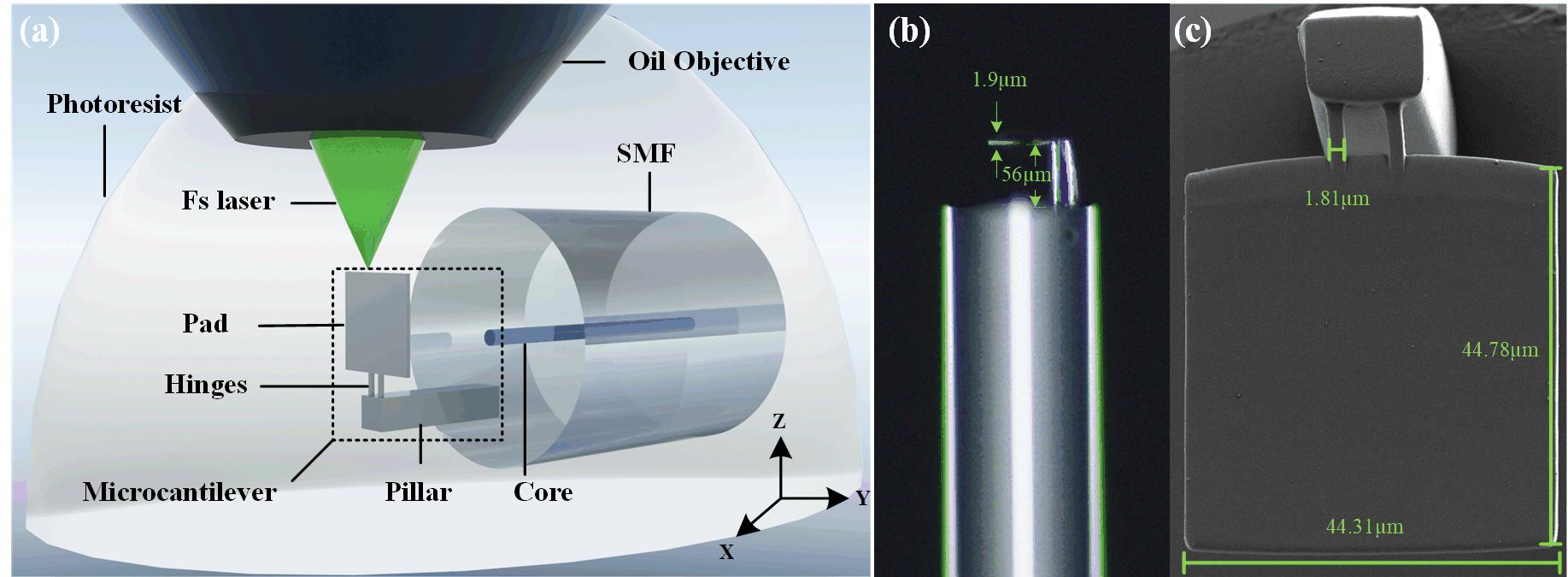

Innovation with TPP Technology: The authors utilize TPP technology, which uses femtosecond lasers for high-precision 3D printing, to fabricate a microcantilever structure directly on the tip of an optical fiber. This method provides sub-micron precision and enhances the flexibility of the microphone, improving acoustic sensitivity. The low Young's modulus of the polymer materials used allows for easy deformation under sound pressure, enhancing sensitivity.

Microcantilever Design: The design features a polymer pad, hinges, and supporting pillars to achieve high acoustic compliance. The sensor forms a dual-beam FPI, simplifying the design and improving sensitivity to sound pressure changes.

Experimental Performance: The sensor demonstrates excellent acoustic sensing performance, reproducing sound accurately across various frequencies, including 50 Hz, 1 kHz, and 20 kHz. It achieves a maximum sensitivity at 6 kHz, likely due to the microcantilever's resonance frequency. The sensor exhibits a high fringe contrast of over 15 dB in its interference fringes, indicating good fabrication quality.

Applications and Future Research: This technology could be further expanded to ultrasonic sensing and other acoustic applications, enhancing its measurement bandwidth. The use of finite element simulations to analyze the mechanical behavior of the microcantilever offers opportunities for future design optimization.

The proposed optical fiber microphone, made with TPP 3D printing technology, achieves superior sensitivity and SNR within the audible frequency range, outperforming traditional designs. Its simple structure and fabrication process offer potential for widespread applications in high-precision acoustic sensing.

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.