This article provides a comprehensive review of the emerging ferroelectric material AlScN (aluminum scandium nitride) and its potential applications in non-volatile memory (NVM) and in-memory computing (IMC). The key highlights of the paper include:

Ferroelectricity and Domain Dynamics: AlScN films exhibit ferroelectric behavior due to the wurtzite structure, offering strong polarization and switching capabilities. The doping of scandium into aluminum nitride (AlN) enables the material to achieve large remanent polarization and coercive electric fields, which are critical for NVM devices. The polarization dynamics, including domain switching and the influence of various factors like Sc doping, temperature, and film thickness, are thoroughly discussed.

Growth Techniques and Optimization: Different deposition techniques for AlScN films such as magnetron sputtering, molecular beam epitaxy (MBE), and metal-organic chemical vapor deposition (MOCVD) are analyzed. The article discusses how parameters like power, pressure, and temperature during the deposition process affect the ferroelectric properties of AlScN, with magnetron sputtering being identified as the most favorable method for large-scale production.

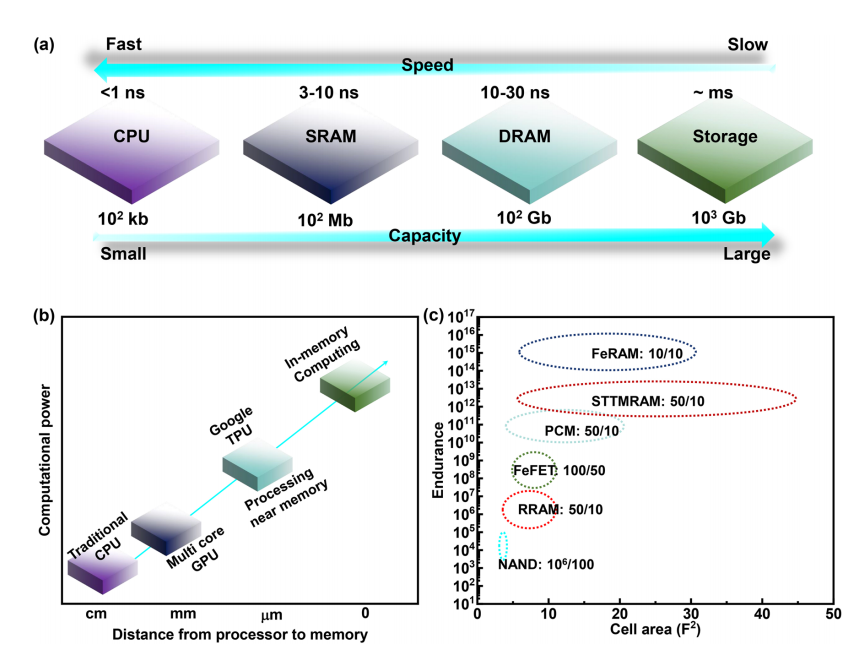

Applications in Ferroelectric Memory: AlScN shows promising potential for ferroelectric random-access memory (FeRAM) and other memory devices, offering high-speed, low-power consumption, and long endurance. It is noted for its compatibility with CMOS technology and its ability to function at low operating voltages, making it suitable for future memory technologies.

Challenges and Perspectives: The paper identifies challenges such as the need for optimized material properties, reduced leakage current, and improved cycling endurance for large-scale integration. Solutions like doping, strain engineering, and scaling down film thickness are suggested to overcome these challenges.

In-Memory Computing: The article highlights the role of AlScN in in-memory computing applications, such as vector-matrix multiplication (VMM) and logic operations, essential for AI and neuromorphic computing. The potential for AlScN-based devices to operate as memristors, ferroelectric diodes, and field-effect transistors (FeFETs) is explored.

In conclusion, AlScN's ferroelectric properties, combined with its CMOS compatibility and scalability, make it a promising material for next-generation memory devices and in-memory computing systems. However, further research is required to address the material-level challenges to ensure its commercial viability.

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.