The paper titled "Bimorph Lithium Niobate Piezoelectric Micromachined Ultrasonic Transducers" explores the design, fabrication, and characterization of advanced piezoelectric micromachined ultrasonic transducers (PMUTs) using a bimorph structure with lithium niobate (LN) as the active layer. Below is a summary of the key findings and contributions:

PMUTs are essential for applications requiring high mechanical durability, thermal stability, and compact size, such as medical imaging, range-finding, and high-temperature sensing. Traditionally, materials like lead zirconate titanate (PZT) and aluminum nitride (AlN) are used in PMUTs, but they have limitations in actuation and sensitivity. The paper focuses on using single-crystal lithium niobate (LN), which offers higher piezoelectric coupling and bidirectional performance compared to traditional materials.

The authors present a bimorph LN PMUT, where two layers of periodically poled piezoelectric lithium niobate (P3F LN) are used to form the active layers. This design does not require intermediate electrode layers, offering improved mechanical robustness and enhanced piezoelectric performance. The LN layer is 20 µm thick, and the device operates at a flexural mode frequency of 775 kHz, with a high voltage sensitivity of 2.4 mV/Pa.

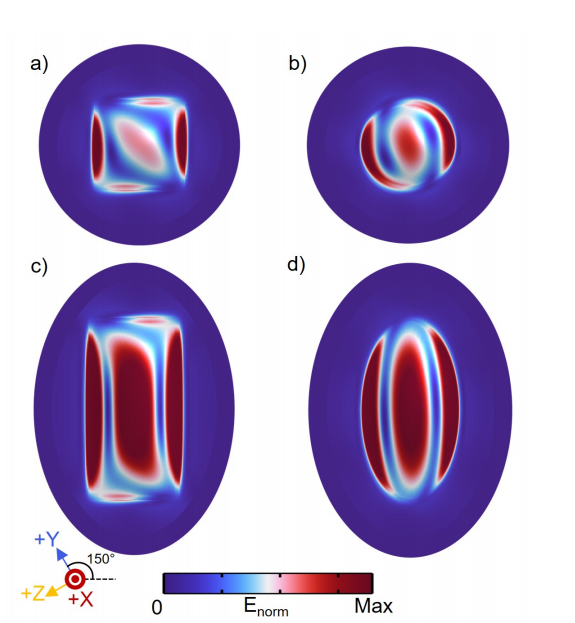

A comprehensive design and simulation process was conducted to optimize the LN PMUT. Key design parameters such as the diaphragm shape, electrode placement, and geometry were adjusted. The authors used finite element analysis (FEA) to account for LN’s in-plane anisotropy. The optimal diaphragm shape was found to be elliptical, which minimized parasitic transverse fields and improved efficiency.

Material properties of LN were compared with those of incumbent PMUT materials, showing that LN offers a balanced combination of high electromechanical coupling coefficients and moderate dielectric loss. The LN PMUT was optimized for high-frequency operation with a peak transduction efficiency of 0.325 nm/V at 775 kHz. This is a significant improvement over traditional PMUT materials.

The device was fabricated using a 20 µm thick bimorph LN film on a silicon substrate. Fabrication steps included photolithography, electron-beam evaporation of metal electrodes, and deep reactive ion etching (DRIE) to release the membrane. Post-processing steps such as packaging and thermal annealing were used to further optimize performance, especially to reduce parasitic feedthrough.

One of the key advantages of the LN PMUT is its thermal resilience. The device demonstrated stable operation up to 600°C and survival up to 900°C, which is a significant achievement for high-temperature applications. The PMUT's performance showed no loss in efficiency up to 600°C, with a temperature coefficient of frequency (TCF) of -319 ppm/K.

Mechanical testing using a laser Doppler vibrometer (LDV) confirmed that the LN PMUT exhibited a flexural mode resonance. Electrical testing was performed to assess impedance and phase response, with the device showing high efficiency despite some residual parasitic feedthrough, which was partially mitigated through annealing.

The paper concludes that bimorph LN PMUTs offer excellent performance, including high transduction efficiency, thermal robustness, and high voltage sensitivity. These devices are suitable for applications in harsh environments, such as high-temperature sensors, and show promise for future development in both ultrasonic sensing and actuation.

The study also discusses remaining challenges, including the need to address parasitic feedthrough and residual fabrication-induced issues. Further work is planned to improve these aspects and optimize the PMUTs for various applications.

Overall, the work demonstrates that LN-based PMUTs could be a transformative platform for high-performance, high-temperature ultrasonic transducers.

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.