Paper Download

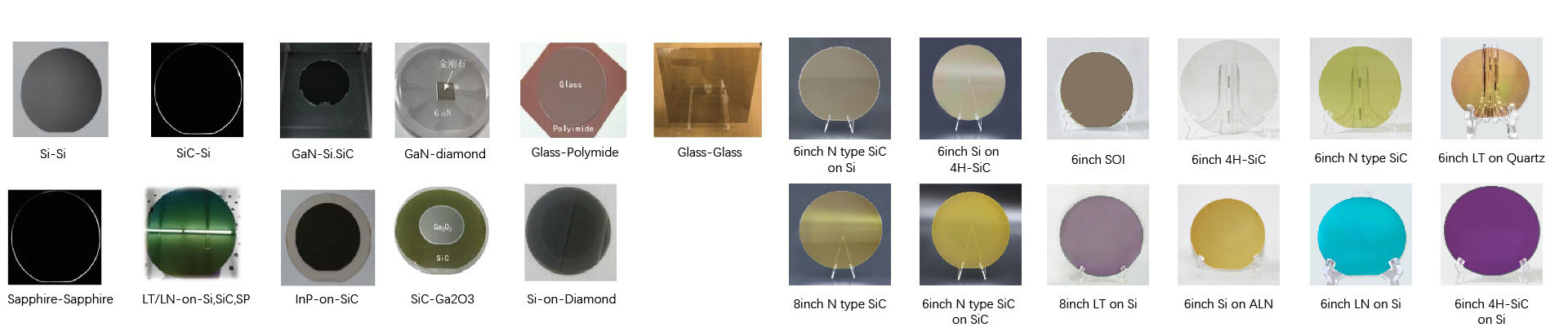

OMedaSemi can provide diverse composite X-o-X Wafer, we use surface actived bonding technology to bond diverse material . you can click this page to know our composite wafer and our surface actived bonding technology

The article titled *"Acoustic Devices (PAW, SAW, and BAW) using Wafer Bonding Technology"* discusses advancements in acoustic wave devices by utilizing wafer bonding techniques. These devices include Plate Acoustic Wave (PAW), Surface Acoustic Wave (SAW), and Bulk Acoustic Wave (BAW) resonators, which are crucial in mobile communication systems. Here’s a summary of the key points:

### Key Highlights:

1. **Wafer Bonding Technology**: By bonding piezoelectric thin plates (such as LiNbO₃ or LiTaO₃) to various substrates (like quartz or glass), high-performance acoustic devices with desirable properties such as high frequency, wide bandwidth, and temperature stability have been realized. Wafer bonding also allows precise thinning of piezoelectric plates.

2. **Device Categories**:

- **PAW Devices**: Lamb wave resonators using ultra-thin LiNbO₃ plates offer high frequencies up to 5.8 GHz and wideband characteristics. Ultra-wideband shear-horizontal (SH0) plate wave devices with large coupling factors (k²) have also been developed.

- **SAW Devices**: Solidly mounted SH-type SAW devices were fabricated using LiNbO₃ thin plates combined with multilayer acoustic films and glass substrates, achieving high Z-ratios and wide bandwidth.

- **HAL SAW Devices**: Hetero Acoustic Layer (HAL) SAW resonators combine LiTaO₃ thin plates and quartz substrates, yielding excellent characteristics like near-zero temperature coefficient of frequency (TCF), high Q-factors, and spurious-free performance.

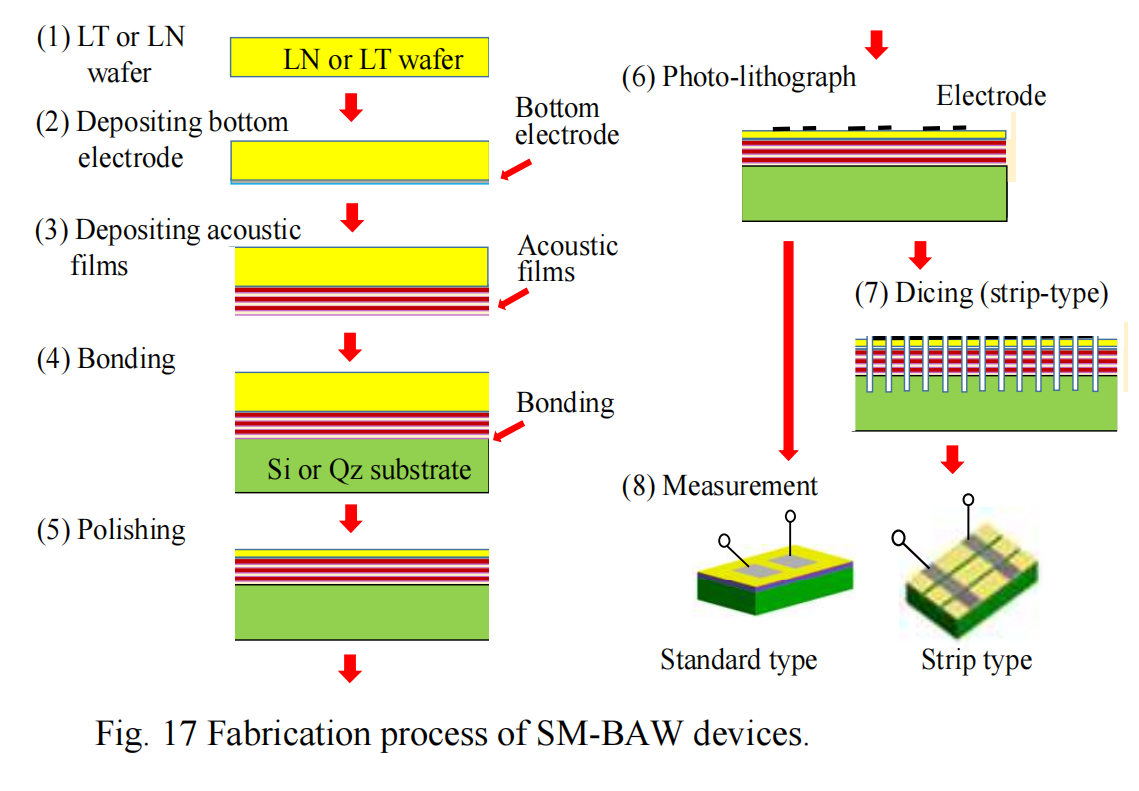

- **BAW Devices**: Solidly mounted BAW resonators (SM-BAWRs) using LiNbO₃ or LiTaO₃ have been developed to achieve high frequencies (up to 9.5 GHz using overtone modes). These devices exhibit wide bandwidth and high-frequency performance.

3. **Performance Improvements**:

- HAL SAW resonators demonstrated superior performance, including wider bandwidths, higher impedance ratios, and excellent temperature stability compared to conventional devices.

- Advances in bonding technology enable high-frequency acoustic devices to meet the increasing demands of modern communication systems, especially for applications requiring miniaturization and energy efficiency.

4. **Applications**: These acoustic devices have potential use in next-generation mobile communication systems, high-frequency filters, and resonators for various RF and microwave applications.

### Conclusion:

The article demonstrates how wafer bonding technology has been instrumental in enhancing the performance of PAW, SAW, and BAW devices by allowing the combination of different materials, improving mechanical strength, and enabling ultra-thin piezoelectric plates. This innovation is critical in advancing telecommunication filters and resonators, especially as the demand for higher frequencies and broader bandwidths continues to rise.

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.