Paper Download

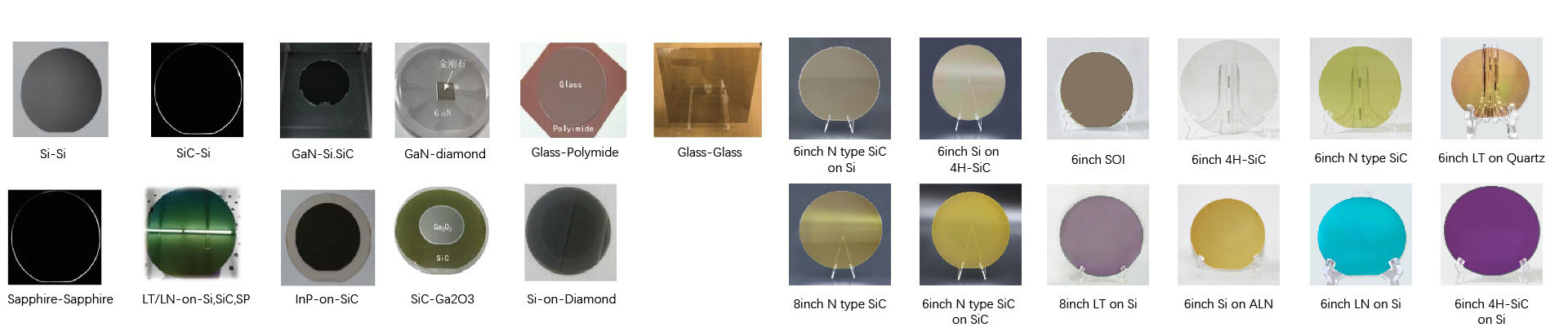

OMedaSemi can provide diverse composite X-o-X Wafer, we use surface actived bonding technology to bond diverse material . you can click this page to know our composite wafer and our surface actived bonding technology

The article "Hetero Acoustic Layer Surface Acoustic Wave Resonator Composed of LiNbO₃ and Quartz" presents research on a surface acoustic wave (SAW) resonator made from a hetero acoustic layer (HAL) of lithium niobate (LiNbO₃ or LN) and quartz (Qz). Here’s a summary:

### Key Points:

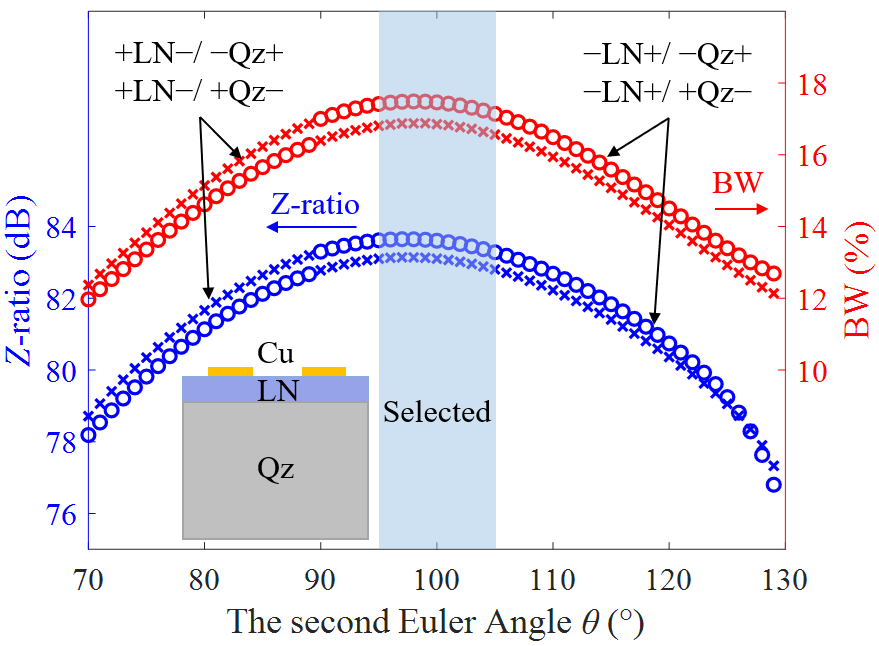

1. **Objective**: The study investigates the development of a shear-horizontal (SH) mode SAW resonator based on an LN/Qz HAL structure. This aims to enhance performance in terms of bandwidth (BW), temperature coefficient of frequency (TCF), and impedance ratio (Z-ratio).

2. **Design and Simulation**: Through simulations using finite element methods (FEM), the researchers optimize the structure by selecting specific Euler angles for LN and Qz, which enhance performance. The study highlights how the HAL structure confines both displacement and electric fields, reducing mechanical loss and improving energy confinement.

3. **Experimental Results**:

- The fabricated resonator achieved a **Z-ratio of 95 dB**, a **BW of 15.9%**, and a **figure of merit (FoM) of 410**, the best reported for LN-based resonators.

- The TCF at anti-resonance was **-77 ppm/°C**, demonstrating good temperature stability.

- Different resonator structures using thin and thick electrodes of LN and LN/Qz were compared, further showing that the LN/Qz resonator outperforms the single LN resonator in terms of energy confinement and overall performance.

4. **Applications**: The results suggest that the LN/Qz HAL SAW resonator holds potential for use in advanced telecommunication filters, offering a wide passband, high Z-ratio, and strong temperature performance.

5. **Challenges**: The study points out the need for further research to address temperature stability and mode suppression in high-frequency applications.

This research makes a significant contribution to the development of high-performance, wideband SAW resonators with potential applications in next-generation communication systems.

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.