The article provides a comprehensive review of the preparation, characterization, and applications of lead zirconate titanate (PZT) thin film sensors. The paper highlights the essential role of piezoelectric materials like PZT in the development of high-precision, miniaturized sensors, including accelerometers, ultrasonic detectors, and other micro-electromechanical systems (MEMS). PZT thin films are integral in the advancement of these sensors, offering superior performance in terms of sensitivity and reliability under varying environmental conditions.

Key points discussed in the article include:

PZT Material Properties: The review emphasizes the piezoelectric properties of PZT, including its high piezoelectric constant and stability over a broad temperature range. The material is widely used due to its ability to generate high sensitivity and electromechanical conversion efficiency under stress.

Manufacturing Methods for PZT: Several methods for producing PZT thin films are detailed:

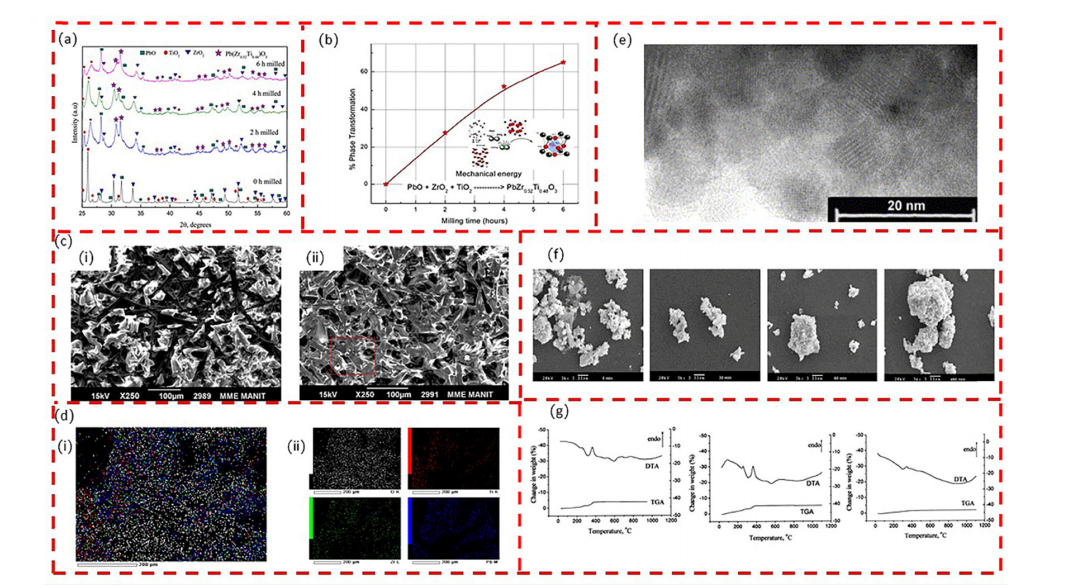

Solid-phase method: A traditional approach that involves high-temperature calcination to form PZT powder, which is then processed into films. Though simple and cost-effective, it suffers from impurities and volatilization of lead elements during high-temperature reactions.

Wet chemical methods: These include the sol–gel, hydrothermal, and precipitation methods, which offer higher purity, smaller particle sizes, and better control over film properties.

Advanced deposition methods: Techniques such as magnetron sputtering, spin coating, and pulsed laser deposition are explored. Each method's advantages and limitations in terms of film quality, deposition rate, and crystal structure are discussed.

Film Characterization and Polarization: PZT thin films require further processing steps such as sintering and polarization to enhance their piezoelectric properties. Sintering promotes grain growth, while polarization aligns the dipoles within the material, enabling the desired piezoelectric effect.

Laser Processing: The review highlights the use of laser processing techniques, such as laser sintering and laser annealing, as alternatives to traditional furnace-based sintering. Laser methods offer advantages in terms of efficiency, local control over temperature, and the ability to process complex shapes, while reducing energy consumption and processing time.

Applications: PZT thin film sensors are widely applied in fields such as biomedical sensors, ultrasonic testing, and MEMS devices. Their small size and high sensitivity make them ideal for these applications, particularly in environments where traditional, bulk piezoelectric materials would be impractical.

The paper concludes by examining future trends in PZT thin film technology, particularly in the areas of flexible electronics and high-performance sensors for IoT applications, emphasizing the potential of these materials in next-generation devices. The ongoing development of fabrication techniques and the integration of advanced processing methods, such as 3D printing and laser sintering, are expected to drive the further miniaturization and optimization of these sensors.

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.