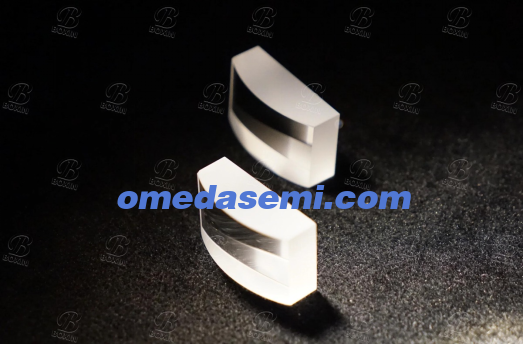

Cylindrical mirrors are not uncommon in high-end optical systems. In line-scanning imaging, laser shaping, and high-power laser systems, cylindrical mirrors often play a key role in "focusing or shaping in just one direction."

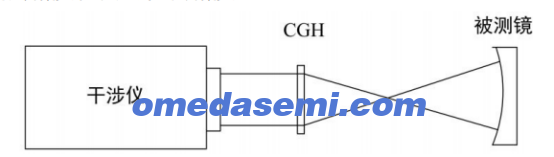

As system performance continues to improve, cylindrical mirrors are also evolving — becoming larger, requiring higher surface shape consistency, and demanding tighter tolerances. Meanwhile, testing is gradually becoming a core component in the manufacturing chain of these optical elements. To address the geometric characteristics of cylindrical mirrors, CGH can introduce one-dimensional phase compensation that matches the cylindrical shape into the interferometer, effectively canceling out the complex wavefront errors. The result is regular, clear, and stable interference fringes that are easily solvable.

Through CGH, cylindrical mirror testing has shifted from being "experience and tuning-dependent" to an engineering process that is repeatable and quantifiable.

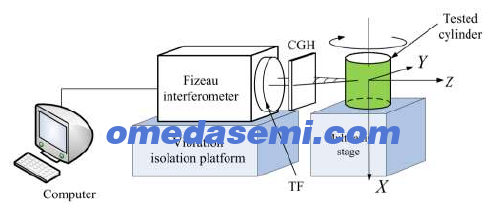

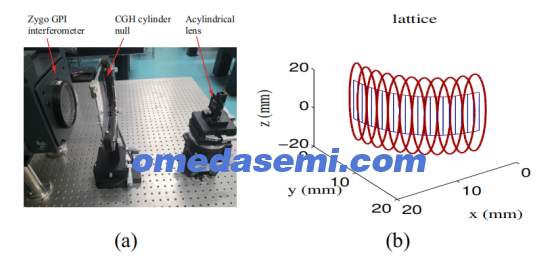

As cylindrical mirrors become larger, stitching measurement has become a necessary choice. In practical applications, the size of cylindrical mirrors often exceeds the coverage area of a single interferometric measurement. Whether due to the interferometer's aperture size or the limitations of CGH fabrication and usage, there are practical constraints. In this case, stitching measurement becomes a more reasonable engineering option. The basic idea is to divide the large cylindrical mirror into multiple sub-regions, measure each segment, and then use the overlapping regions to stitch the data together to reconstruct the overall surface shape.

Diagram of Cylindrical Mirror Stitching

Division of the Measured Cylindrical Mirror Sub-apertures

With reasonable stitching strategies and algorithm support, this solution strikes a good balance between precision, flexibility, and cost, and is increasingly adopted in high-end applications.

High‑precision CGH design and fabrication — please contact Shanghai Omeda: https://www.omedasemi.com

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.