Paper Download

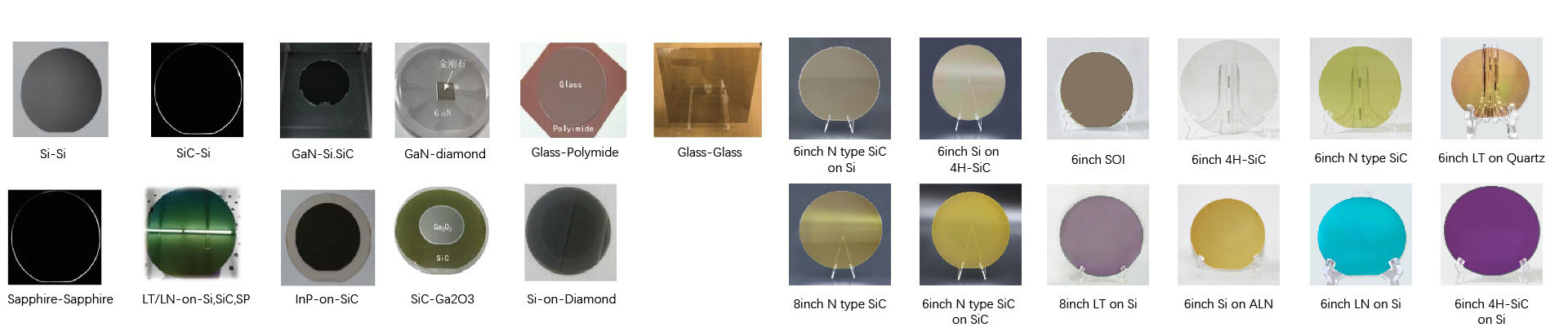

OMedaSemi can provide diverse composite X-o-X Wafer, we use surface actived bonding technology to bond diverse material . you can click this page to know our composite wafer and our surface actived bonding technology

The article titled **"Ultra-Wideband Surface Acoustic Wave Filters Based on the Cu/LiNbO₃/SiO₂/SiC Structure"** focuses on the development of ultra-wideband surface acoustic wave (SAW) filters for high-speed wireless communication systems.

### Key Points:

1. **Objective**:

- The study aims to create ultra-wideband SAW filters with a fractional bandwidth larger than 24% for applications in 5G communication systems, specifically targeting bands like n77, n78, and n79.

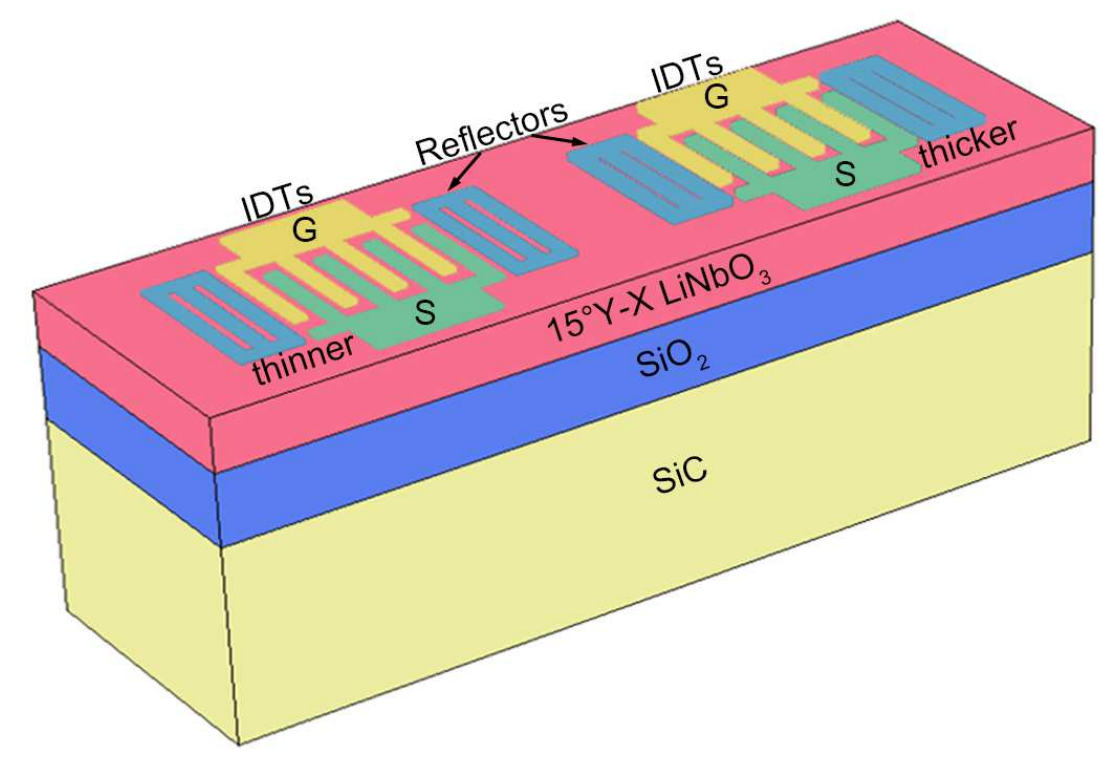

- The structure studied is a multilayer combination of Cu/15°Y-X LiNbO₃/SiO₂/SiC.

2. **Materials and Structure**:

- The multilayered substrate includes 15°Y-X LiNbO₃ (300 nm), SiO₂ (600 nm), and SiC. The use of copper (Cu) for interdigital transducers (IDTs) enhances electrical conductivity and helps suppress unwanted modes.

- This structure combines the properties of different materials to improve acoustic wave confinement, thermal stability, and performance.

3. **Simulation and Fabrication**:

- SAW resonators were simulated with various Cu thicknesses and wavelengths, and the best performance was achieved with a Cu thickness of 0.12λ.

- Resonators were fabricated and evaluated using finite-element simulations, with key performance parameters such as electromechanical coupling (K²), phase velocity, and temperature stability.

4. **Filter Design**:

- Based on the resonator results, a ladder-type SAW filter was designed. Series and shunt resonators were combined to achieve ultra-wideband performance. The center frequency of the filter was measured at 1.46 GHz, with a fractional bandwidth (FBW) of 31.08%.

- The filter achieved a low insertion loss of 0.84 dB, making it suitable for high-performance wireless communication applications.

5. **Temperature Stability**:

- The filter's performance was stable over a wide range of temperatures, with temperature coefficients of -69.7 ppm/°C (lower edge) and -54.4 ppm/°C (higher edge). This represents a significant improvement in temperature stability over previous designs.

### Conclusion:

The study demonstrates the potential for fabricating ultra-wideband and low-loss SAW filters using the Cu/LiNbO₃/SiO₂/SiC multilayered structure. The filter’s performance, with a 3-dB FBW of 31.08%, shows promise for commercial applications in 5G communication systems.

This work is a step forward in developing high-performance filters for wireless communication, offering better bandwidth and stability than traditional designs【17†source】.

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.