Paper Download

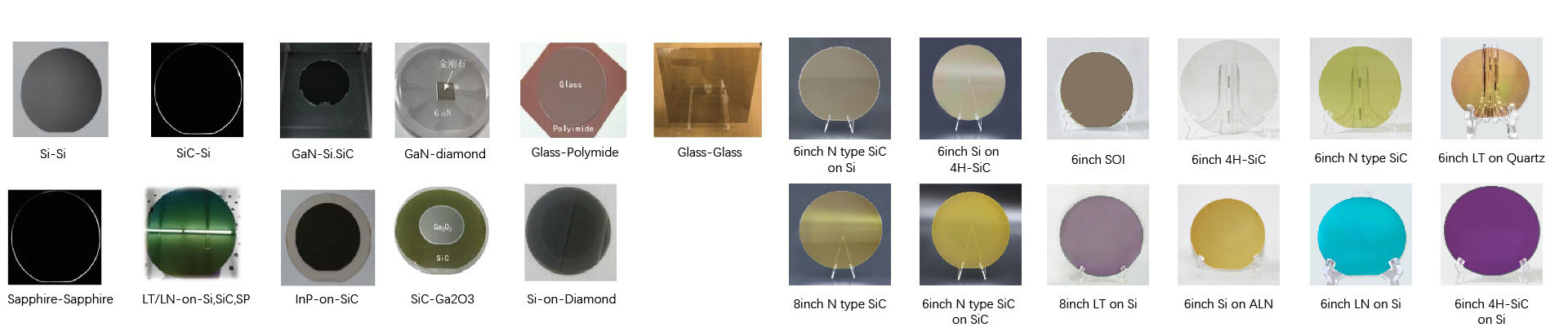

OMedaSemi can provide diverse composite X-o-X Wafer, we use surface actived bonding technology to bond diverse material . you can click this page to know our composite wafer and our surface actived bonding technology

The article titled **"Near 6-GHz Longitudinal Leaky SAW Filters with Spurious Mitigation on LiNbO₃/SiO₂/SiC Platform"** discusses the development of high-frequency, spurious-free longitudinal leaky surface acoustic wave (LLSAW) filters for advanced 5G and WiFi 6 applications.

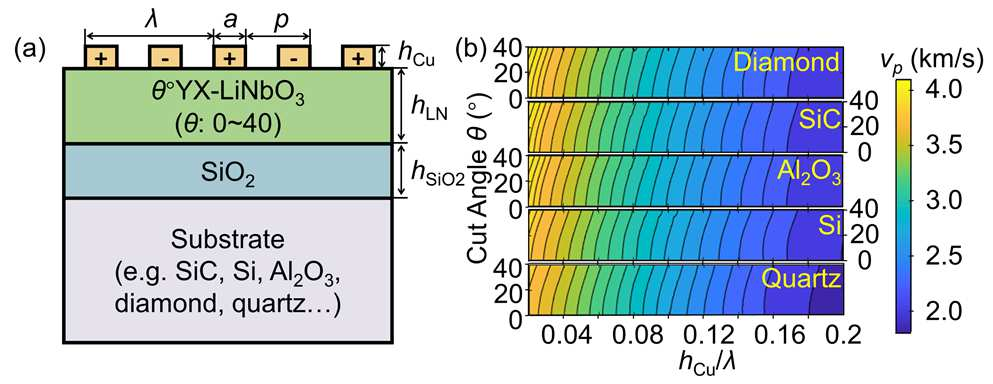

The article titled "Enlarging Rayleigh Elimination Window through Modulating Substrate and LiNbO₃ Cut Angle for Fabricating LNOI-Based Spurious-Free Wideband SAW Filters" focuses on improving the design of wideband surface acoustic wave (SAW) filters using a lithium niobate on insulator (LNOI) platform. The main findings are as follows:

1. **Objective**: The study aims to investigate the effects of substrate materials and lithium niobate (LN) cut angles on the Rayleigh elimination window (REW), which is essential for creating spurious-free wideband SAW filters. The REW refers to a range where Rayleigh modes are eliminated, thereby reducing interference.

2. **Methodology**:

- The authors used finite element method (FEM) simulations to study different substrate materials (SiC, Si, Al₂O₃, diamond, and quartz) and LN cut angles.

- They fabricated resonators and filters on rotated YX-LN/SiO₂/substrate platforms and tested them.

3. **Key Findings**:

- The LN/SiO₂/SiC platform exhibited the widest REW, indicating the elimination of Rayleigh modes in a Cu electrode normalized thickness range (ΔhCu/λ) of 0.08 when the cut angle (θ) was between 18° and 24°.

- Filters fabricated on the 20° and 25° YX-LN/SiO₂/SiC platforms were spurious-free and showed a 3-dB fractional bandwidth (FBW) of approximately 20% with a minimum insertion loss (ILmin) of about 1.2 dB.

4. **Conclusion**: The results provide a guideline for designing spurious-free wideband SAW filters, which can aid the development of 5G front-end integration by optimizing the LNOI platform through substrate and cut angle modulation.

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.