Paper Download

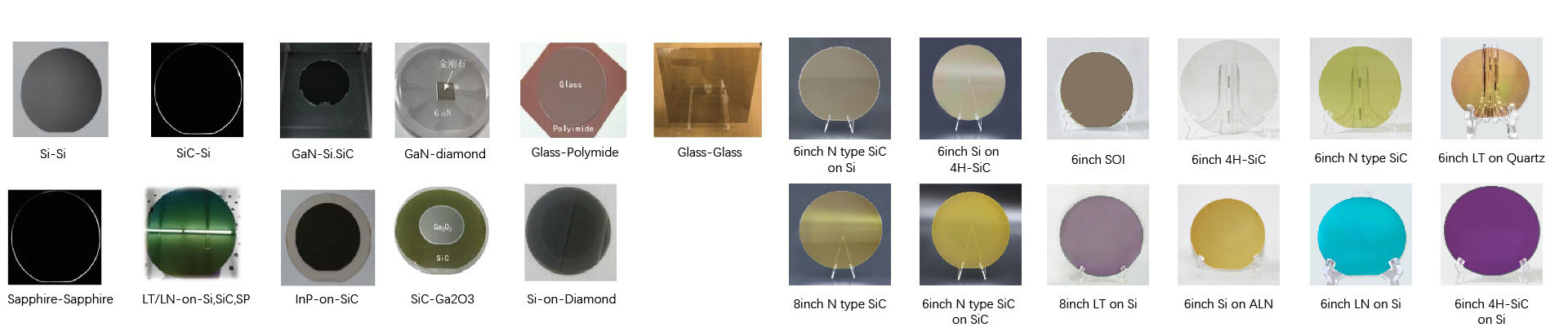

OMedaSemi can provide diverse composite X-o-X Wafer, we use surface actived bonding technology to bond diverse material . you can click this page to know our composite wafer and our surface actived bonding technology

The article titled **"Near 6-GHz Longitudinal Leaky SAW Filters with Spurious Mitigation on LiNbO₃/SiO₂/SiC Platform"** discusses the development of high-frequency, spurious-free longitudinal leaky surface acoustic wave (LLSAW) filters for advanced 5G and WiFi 6 applications.

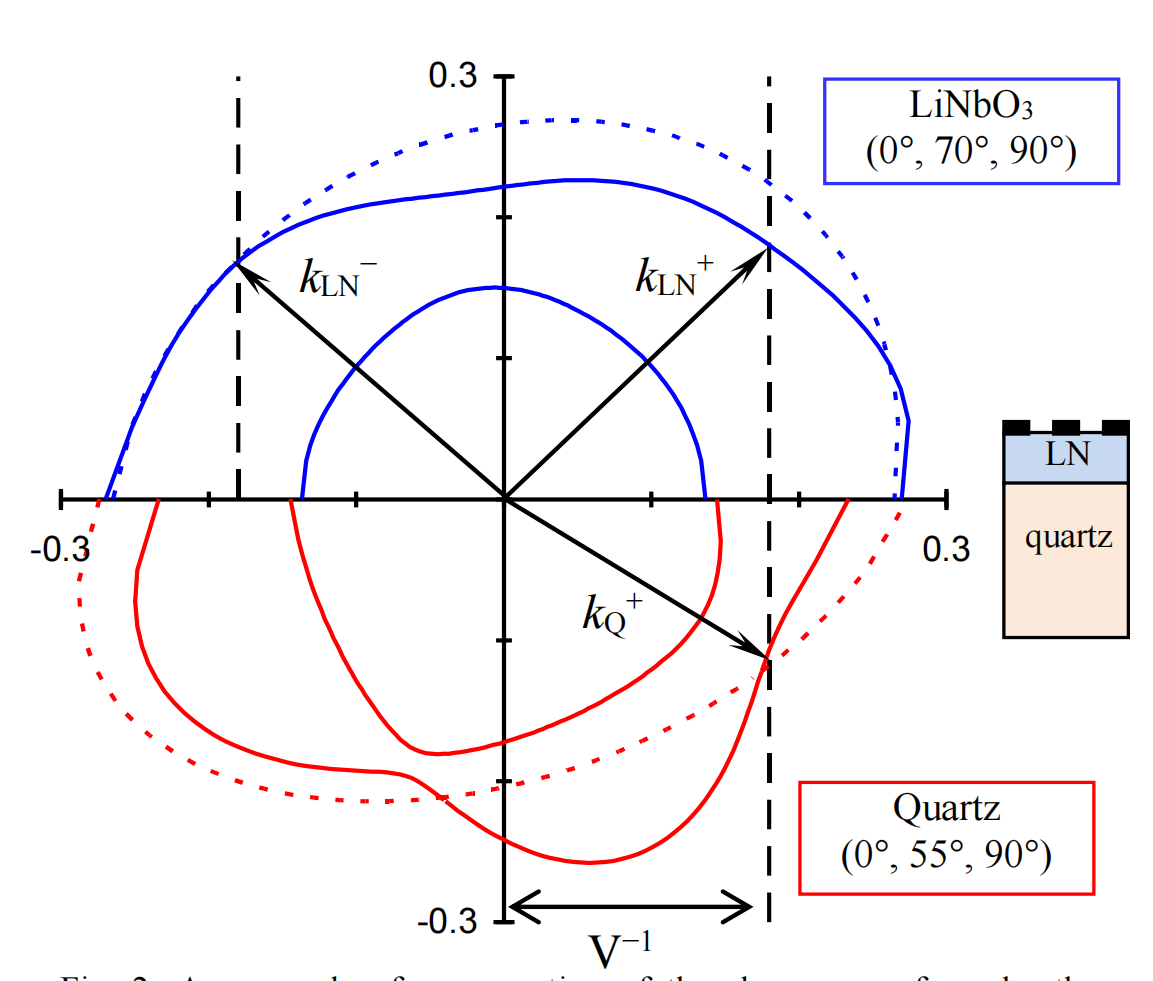

The article titled "LiNbO₃ Plate Bonded to Quartz as a Substrate for High Frequency Wideband SAW Devices" focuses on the use of bonded wafers combining a thin lithium niobate (LiNbO₃) plate with a quartz substrate for high-frequency wideband surface acoustic wave (SAW) devices. Here are the key points:

1. **Objective**: The study aims to explore bonded multilayer structures as potential substrates for high-frequency wideband SAW filters, targeting high velocity, high electromechanical coupling, and minimal propagation losses.

2. **Key Findings**:

- Longitudinal leaky waves with velocities up to 7000 m/s were investigated.

- The optimized structures showed non-attenuated waves propagating at velocities between 5500-6200 m/s with electromechanical coupling up to 18%.

- High-quality factors (Q > 5000) were achieved at resonant and anti-resonant frequencies when the duty factor of the electrode structure varied between 0.48 and 0.65.

- The optimal plate and electrode thicknesses were found to be 40% and 5% of a wavelength, respectively, making these structures suitable for SAW resonators operating at frequencies up to 5 GHz.

3. **Significance**: The study demonstrates that the LiNbO₃/quartz structure, when optimized, offers a promising solution for developing high-frequency, wideband SAW filters, potentially benefiting the next generation of communication systems.

The findings provide valuable insights into using LiNbO₃/quartz as a substrate for high-performance SAW devices, showing the possibility of achieving high velocity and wide bandwidth with minimal losses.

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.