Paper Download

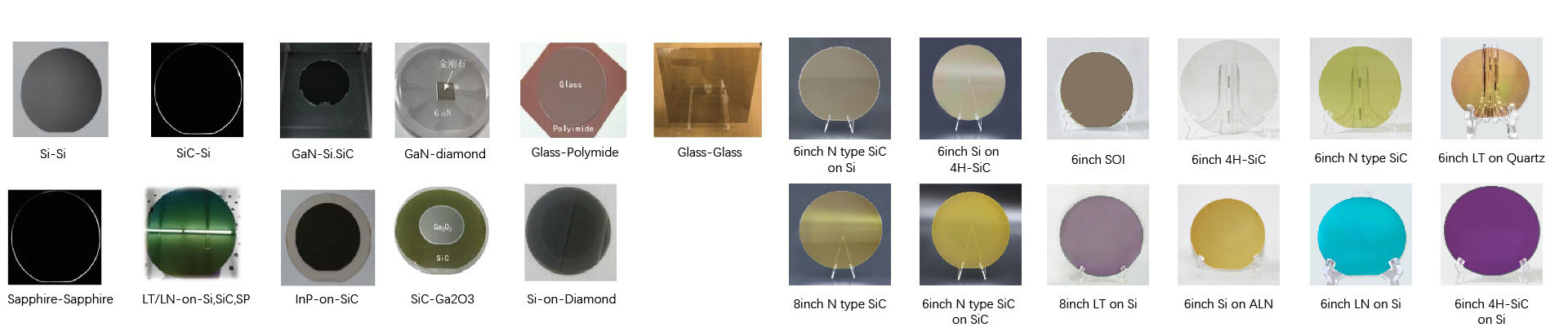

OMedaSemi can provide diverse composite X-o-X Wafer, we use surface actived bonding technology to bond diverse material . you can click this page to know our composite wafer and our surface actived bonding technology

The article titled "Evolution of SAW and BAW Devices Using Thin LiTaO₃ and LiNbO₃" reviews the development of Hetero Acoustic Layer (HAL) devices using thin lithium tantalate (LiTaO₃ or LT) and lithium niobate (LiNbO₃ or LN). Here are the main points:

1. **Objective**: The study explores three types of HAL devices using thin LT and LN, focusing on their performance and potential applications in surface acoustic wave (SAW) and bulk acoustic wave (BAW) devices.

2. **Key Findings**:

- **LT-on-Quartz HAL SAW Device**: The LT/quartz combination showed promising performance, including a high impedance ratio (up to 84 dB) and near-zero temperature coefficient of frequency (TCF). A proprietary method was developed to bond LT to quartz, and the results showed that polarity significantly affects the device's performance.

- **LN-on-Quartz HAL SAW Device**: The LN/quartz combination exhibited an extremely high impedance ratio (up to 95 dB) and ultra-wide bandwidth (about 16%). The TCF was high but could be reduced by adding amorphous SiO₂.

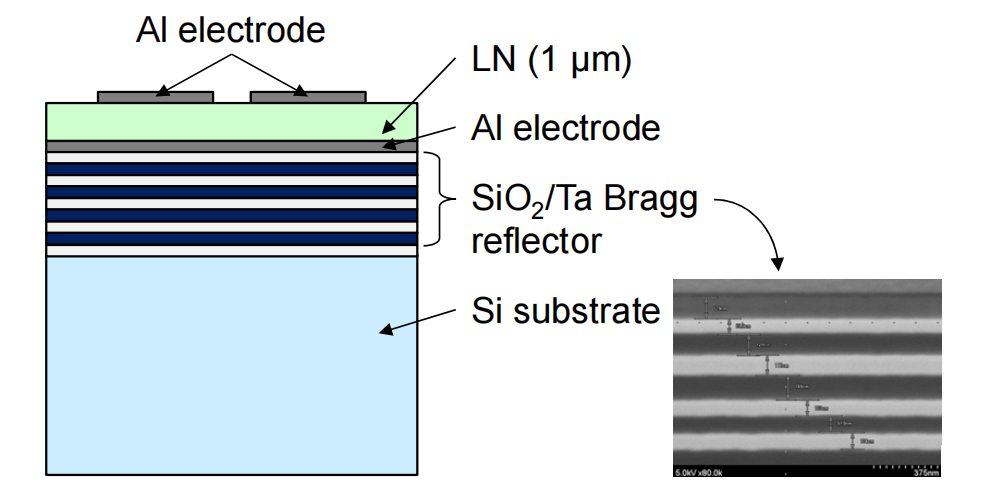

- **Solidly-Mounted LN Overtone Resonator**: A third overtone resonator with 1 μm thick LN and a SiO₂/Ta Bragg reflector demonstrated a strong third overtone response at 9.5 GHz, with a 1% bandwidth and a 31 dB impedance ratio.

3. **Significance**: The study confirms that HAL devices using LT/quartz and LN/quartz are promising for practical filter applications. The results also highlight the potential of thin LN/LT in high-frequency BAW devices, such as overtone resonators operating around 10 GHz.

4. **Future Prospects**: The article suggests that there is room for improvement in device design, particularly using MEMS process technology, and mentions ongoing exploration inspired by XBAR (A1 cutoff resonators).

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.