Paper Download

We provide 4-6 inch SICOI wafers (silicon carbide on insulator wafers). The wafers use surface activated bonding technology to bond thermal oxide wafers and 4H high-purity semi-insulating silicon carbide wafers together, and then control the thickness to the thickness you need through ion implantation, annealing, thinning or direct thinning and CMP polishing. It is worth noting that ion implantation and direct CMP and thinning have their own advantages and disadvantages.we also have many stock ,you can visit this page to know more : SICOI Wafer( Silicon Carbide on Insualtor)

The article titled **"4H-Silicon Carbide as an Acoustic Material for MEMS"** provides a detailed study of the properties of 4H-silicon carbide (4H-SiC) as an acoustic material for use in microelectromechanical systems (MEMS). Here's a summary of the key points:

1. **Superiority of 4H-SiC for MEMS**:

- 4H-SiC is identified as a superior material for MEMS applications due to its excellent mechanical, acoustic, electrical, and thermal properties. It outperforms silicon in high-performance and extreme environments (such as high temperatures, pressures, and corrosive conditions).

- Properties such as high elastic modulus, fracture strength, chemical inertness, and acoustic velocity make 4H-SiC ideal for MEMS resonators, sensors, and other high-performance applications.

2. **Transverse Isotropy**:

- 4H-SiC exhibits transverse isotropy, meaning its mechanical properties are uniform in the plane perpendicular to the c-axis, making it more stable and reliable for MEMS applications.

- This reduces issues like frequency splitting and ensures better performance in gyroscopic and resonant applications, compared to materials like 3C-SiC or silicon.

3. **Elastic Properties and Quality Factor**:

- 4H-SiC has lower phonon scattering, leading to an ultra-high quality factor (Q-factor), which is critical for MEMS resonators, resulting in energy-efficient and precise devices.

- The material's elastic properties, particularly its Young’s modulus and shear modulus, contribute to its high performance. The paper also discusses methods for extracting elastic constants and compares 4H-SiC to other SiC polytypes and materials like silicon.

4. **Temperature-Dependent Properties**:

- The paper examines the temperature coefficient of frequency (TCF) and the temperature coefficient of Q-factor (TCQ) for 4H-SiC resonators. 4H-SiC resonators show a lower TCF than silicon or quartz, making them more stable in varying temperatures.

- A positive TCQ (quality factor increasing with temperature) was observed, which is uncommon and suggests that 4H-SiC could offer significant advantages for applications requiring high stability across temperature ranges.

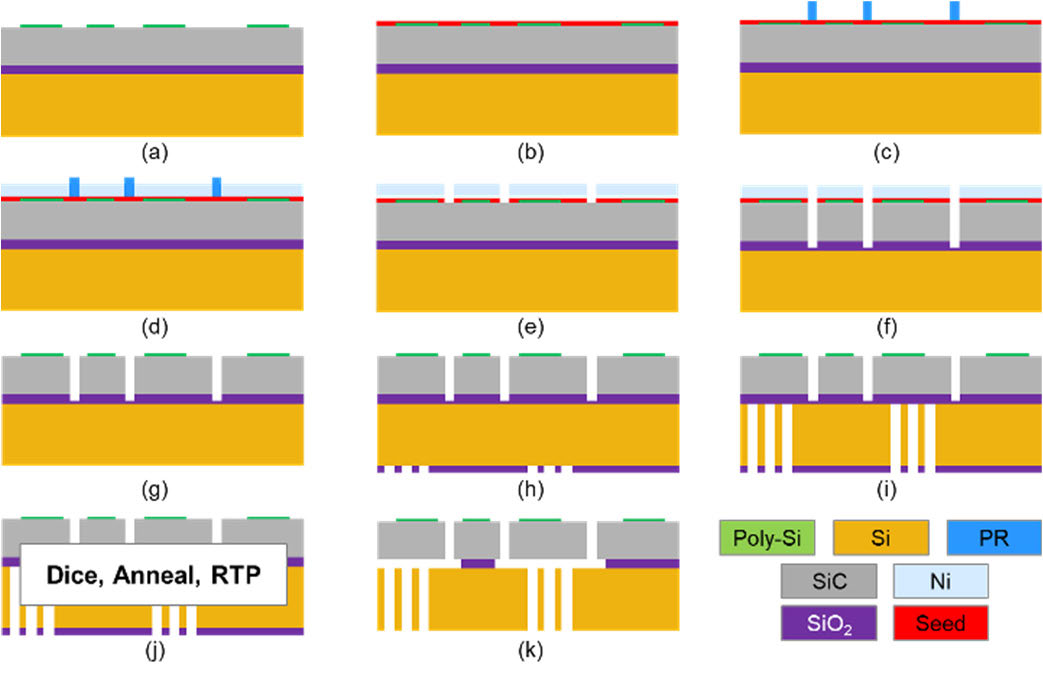

5. **Fabrication Techniques**:

- The paper discusses the fabrication of 4H-SiC-on-insulator (4H-SiCOI) platforms using bonding and etching techniques. Challenges in deep reactive ion etching (DRIE) and bonding due to material properties are outlined, but the development of reliable processes like Smart-Cut™ and oxidation bonding are highlighted.

- These fabrication techniques enable the creation of MEMS devices with high aspect ratios and minimal losses.

6. **Applications and Future Trends**:

- 4H-SiC is considered promising for a wide range of MEMS applications, including inertial sensors, timing devices, and resonators for use in extreme environments.

- The paper calls for further research to overcome fabrication challenges and enhance the material's potential for precision applications, including gyroscopes, accelerometers, and integrated MEMS devices for harsh conditions.

In conclusion, the article emphasizes that 4H-SiC is a highly suitable material for the next generation of MEMS devices, particularly in challenging environments, and highlights its exceptional mechanical and acoustic properties. The research sets a strong foundation for future advancements in MEMS technology using 4H-SiC.

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.