Paper Download

We provide 4-6 inch SICOI wafers (silicon carbide on insulator wafers). The wafers use surface activated bonding technology to bond thermal oxide wafers and 4H high-purity semi-insulating silicon carbide wafers together, and then control the thickness to the thickness you need through ion implantation, annealing, thinning or direct thinning and CMP polishing. It is worth noting that ion implantation and direct CMP and thinning have their own advantages and disadvantages.we also have many stock ,you can visit this page to know more : SICOI Wafer( Silicon Carbide on Insualtor)

The article titled **"4H Silicon Carbide Bulk Acoustic Wave Gyroscope with Ultra-High Q-Factor for On-Chip Inertial Navigation"** explores the development of high-performance gyroscopes based on 4H-silicon carbide (4H-SiC) for use in inertial navigation systems. Here is a summary of the key points:

1. **Background and Motivation**:

- The study addresses the limitations of silicon-based microelectromechanical system (MEMS) gyroscopes, particularly issues related to noise and stability, which hinder their performance in navigation-grade applications.

- Silicon carbide (SiC), especially its monocrystalline 4H polytype, is proposed as an alternative material due to its superior properties such as low phonon dissipation and high thermal stability.

2. **Device Overview**:

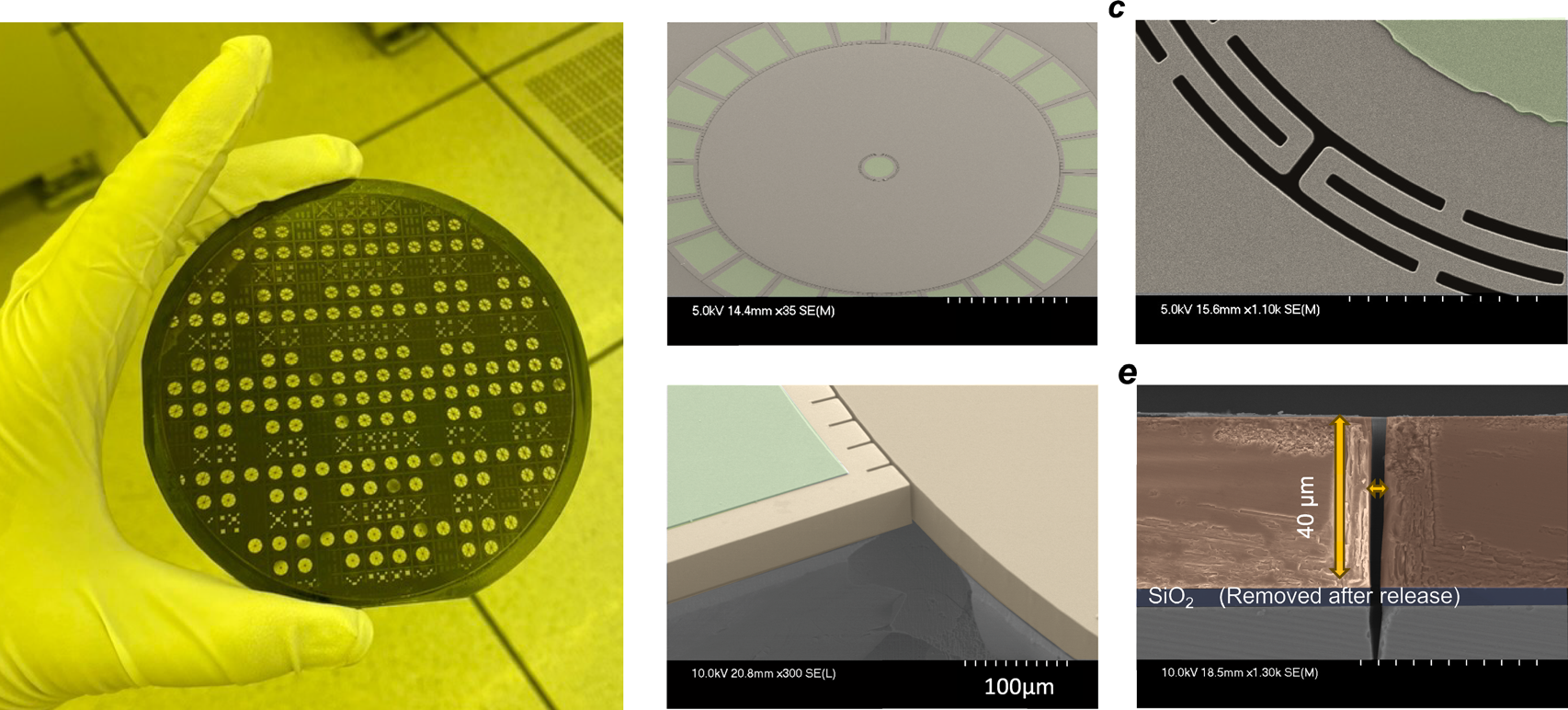

- The research focuses on bulk acoustic wave (BAW) resonant gyroscopes fabricated on 4H-SiC-on-insulator (SiCOI) wafers.

- These gyroscopes operate at megahertz frequencies using BAW modes, which enhance sensitivity and bandwidth compared to traditional MEMS gyroscopes.

3. **High Q-Factor Performance**:

- The gyroscope demonstrates an ultra-high mechanical quality factor (Q) exceeding 4.6 million at 80°C, which significantly improves noise performance, scale factor, and bias instability.

- The device operates in an ovenized environment to stabilize performance across temperature variations, with the Q-factor improving as the temperature increases.

4. **Fabrication and Design**:

- The gyroscopes were fabricated using wafer-level deep reactive ion etching (DRIE) on bonded SiCOI wafers. The design includes a 40 µm thick 4H-SiC layer and 3.5 µm capacitive transduction gaps, which allow for efficient electrostatic actuation.

- The use of 4H-SiC provides better mode matching and less energy dissipation due to its hexagonal crystal structure, resulting in lower coupling with the substrate and higher Q-factors.

5. **Gyroscope Performance**:

- The device achieves an angle random walk (ARW) of 0.005°·h⁻¹/² and bias instability (BI) of 0.34°·h⁻¹ in an open-loop configuration, placing it between tactical and navigation-grade gyroscopes.

- The gyroscope’s performance improves with ovenization, making it suitable for use in high-temperature environments where stability is critical.

6. **Applications and Future Outlook**:

- This gyroscope technology has potential applications in autonomous navigation, precision IMUs, and military-grade inertial sensors due to its combination of high Q-factors, low noise, and temperature stability.

- Future improvements include further reduction in capacitive gap size and enhancing fabrication techniques to reduce the tuning voltage and improve the overall performance of the gyroscope for long-term inertial navigation systems.

In conclusion, the study demonstrates that 4H-SiC-based gyroscopes offer significant improvements in performance compared to silicon-based MEMS devices, with the potential to meet the stringent requirements of navigation-grade inertial sensors.

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.