In 1971, A. J. MacGovern and J. C. Wyang of the U.S. company Itek proposed the use of computed holograms (Computer Generated Holograms, CGH) in interferometric measurements for testing aspheric surfaces. Since then, this technology has been widely applied in the inspection of high-precision optical components, including aspheric surfaces, freeform surfaces, cylindrical mirrors, and others.

When interferometric principles are used to measure the surface figure of a test surface, a matching reference surface is required. Typically, interferometer manufacturers provide only standard plane and spherical reference optics, which allow direct measurement of planar or spherical surfaces. As a result, aspheric, freeform, or cylindrical surfaces cannot be measured directly by interferometry. In such cases, a compensator is required to compensate for wavefront aberrations.

A computed hologram (CGH) is a type of compensating element. It utilizes the diffraction effect of light to compensate for the aberrations introduced by the optical element under test.

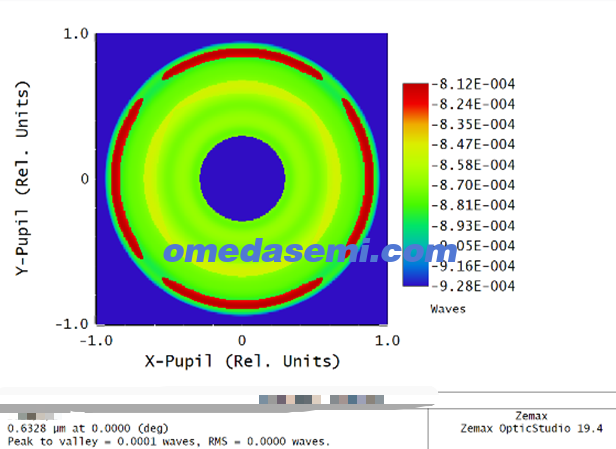

In Zemax, CGH diffractive surfaces are commonly represented using surface types such as Binary 1, Binary 2, and Zernike Fringe Phase.

Binary 1 is suitable for CGH design in cylindrical surface testing.

Binary 2 is commonly used for on-axis aspheric CGH design.

Zernike Fringe Phase can represent complex surface profiles and conveniently incorporate carrier information such as tilt and off-axis terms (to avoid ghost image interference). It is applicable to CGH designs for aspheric, freeform, off-axis, and cylindrical surfaces.

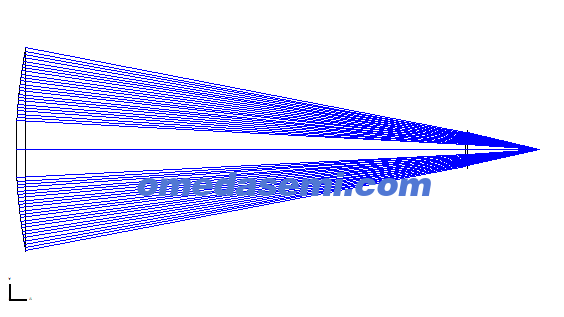

The following example shows a CGH design for an on-axis aspheric surface, with a residual wavefront aberration of zero.

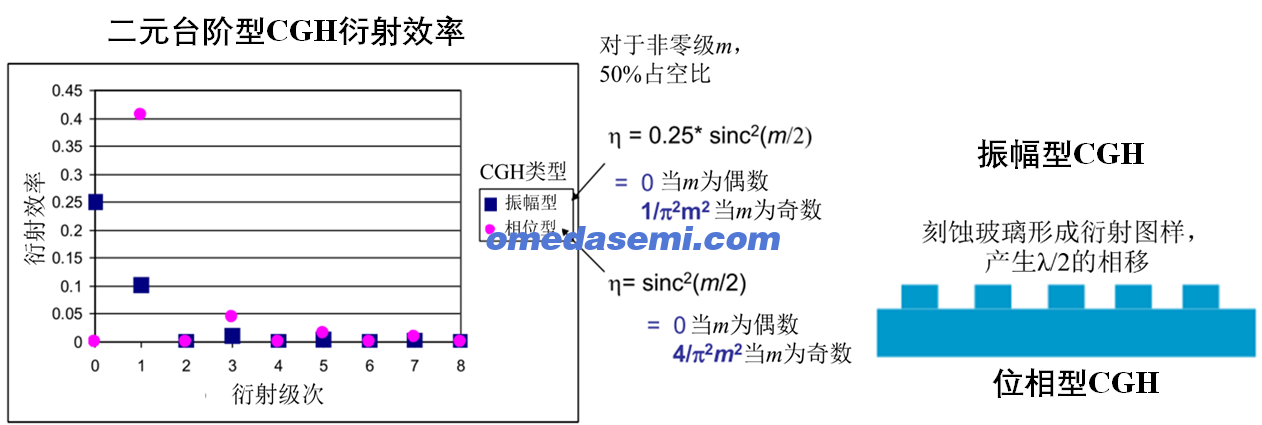

After completing the CGH design in Zemax, the surface phase data must be converted into manufacturable data formats, such as CIF or GDSII, for processes like laser direct writing. CGHs can be classified into amplitude-type, phase-type, or hybrid CGHs.

Amplitude-type CGH: The CGH pattern is formed by depositing chromium on the substrate surface.

Phase-type CGH: The CGH is fabricated by etching a specific phase depth into the substrate (for example, a two-level etch depth of λ / [2(n − 1)], where λ is the test wavelength and n is the refractive index of the material).

When the duty cycle is 0.5, the maximum diffraction efficiency of the ±1st order is approximately:

10% for amplitude-type CGHs

40% for phase-type CGHs

Amplitude-type CGHs are typically used for high-reflectivity mirror surfaces, while phase-type CGHs are suitable for uncoated, low-reflectivity mirror surfaces.

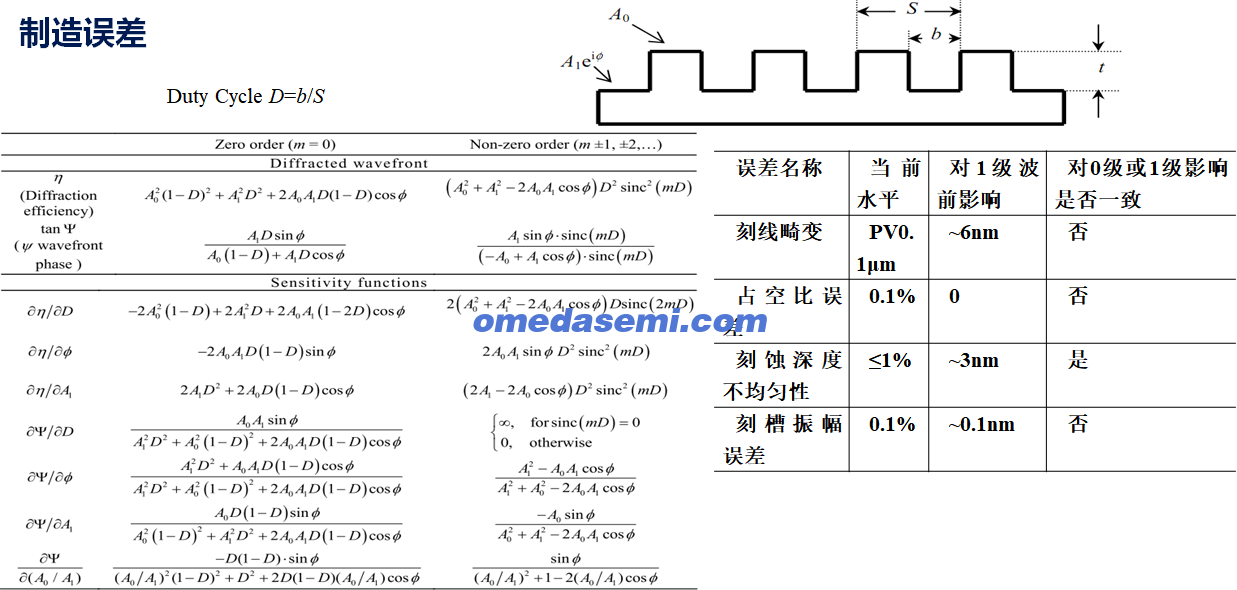

The accuracy of a CGH is determined by several factors, including the surface figure of the substrate material, the transmitted wavefront quality, and the fabrication accuracy of the diffractive pattern. For example, if the accuracy of the mirror under test is λ/30, the transmitted wavefront quality of the CGH substrate should be at least better than λ/60. High-precision substrates are therefore critical to CGH fabrication.

Currently, our company can provide substrates with accuracies ranging from λ/100 to λ/600. Errors in the linewidth and depth of the diffractive microstructures affect not only the diffraction efficiency of the CGH but also introduce wavefront errors. These effects must be analyzed for each specific design, and corresponding fabrication requirements should be defined based on the analysis.

Among all error sources, CGH groove position error is one of the most significant contributors to CGH wavefront error. At present, the groove position accuracy achievable by our high-precision laser direct writing or electron-beam lithography processes ranges from 100 nm down to 10 nm.

High‑precision CGH design and fabrication — please contact Shanghai Omeda: https://www.omedasemi.com

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.