Why is CGH becoming increasingly indispensable for aspheric surface testing?

In recent years, aspheric surfaces have almost become a "standard feature" in high-end optical systems. From smartphone imaging, automotive lenses, and LiDAR to precision instruments, the higher the performance, the more aspheres are involved. However, on the manufacturing side, the real challenge is often not "whether it can be made," but "how to accurately measure it." Among many testing solutions, CGH is becoming an increasingly common and critical technology in the industry.

Traditional interferometric testing is very suitable for spherical surfaces. A standard reference mirror can produce clear and stable interference fringes. But as soon as an aspheric surface is introduced, the situation changes drastically: the reflected wavefront is highly complex and mismatches severely with the ideal reference wavefront. The interference fringes become dense and distorted, almost impossible to interpret. Simply put: the reference wavefront cannot keep up with the "complexity" of the aspheric surface. This is why many high-performance aspheric surfaces are not "impossible to measure," but rather "impossible to measure directly."

Illustration of aspheric interference fringes (fringes are clearly "broken")

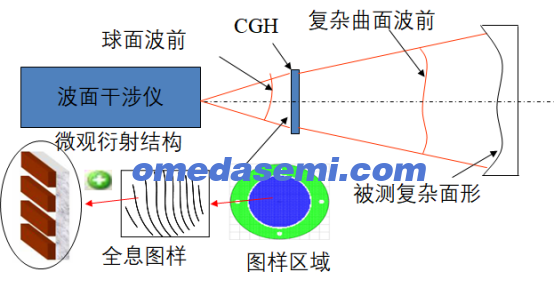

CGH (Computer Generated Hologram) is essentially a diffractive optical element created through precise computation and micro-nano fabrication. In aspheric surface testing, it does one thing: it preemptively "creates" a reference wavefront that perfectly matches the aspheric surface. When light passes through the CGH, it is no longer a simple spherical wave but is "customized" into a complex wavefront that corresponds to the aspheric surface under test. The result is that the aspheric surface "appears" like a normal spherical surface in the interferometer. The interference fringes become sparse, regular, and solvable. In short: CGH transforms an "unmeasurable complex problem" into a "controllable standard measurement."

Illustration of CGH working principle: spherical wave → CGH → complex reference wavefront

CGH is not a new technology, but its rise to prominence is closely related to three trends:

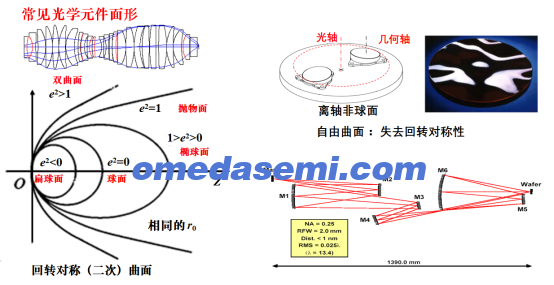

Increasing use of aspheres and freeform surfaces: As system performance increases, the surface profiles become more complex, and traditional testing methods are struggling to keep up.

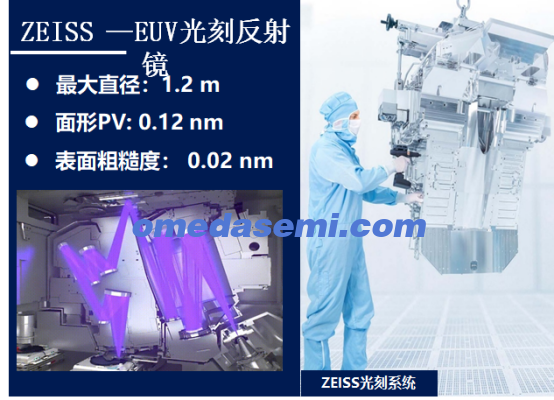

Improved manufacturing precision: While it is now possible to create these complex surfaces, testing them accurately has become the critical bottleneck in the manufacturing process.

Mature computing and fabrication capabilities: Advanced precision computing, photolithography, and laser direct writing have turned CGH from a "laboratory solution" into an engineering tool. In high-end optical manufacturing, CGH is gradually transitioning from a "specialized solution" to one of the default options.

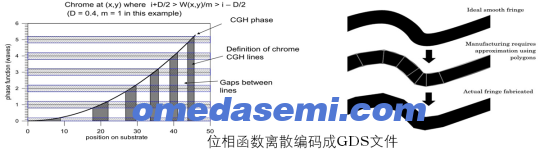

Based on the design model of the aspheric surface, calculate the theoretical wavefront and compare it with the ideal reference wavefront to obtain the optical path difference.

Encode the optical path difference into the phase structure of the CGH.

Fabricate the CGH and install it in the interferometer for measurement.

Solve for the aspheric surface errors.

The core goal of the entire process is simple: to make the interferometer "understand" the aspheric surface.

High‑precision CGH design and fabrication — please contact Shanghai Omeda: https://www.omedasemi.com

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.