Paper Download

OMedaSemi provide Two Photon 3D Printing Service,we use Nanoscribe Phtonics GT2 Pro & Nanoscribe Quantum X and Nanoscribe IP Dip Glue to print nanostructure on most of substrate(Glass Silicon Fiber) ,you can visit this page to know more : Two Photo Polymerization 3D Printing Service

The article "3D Printed Singlet and Doublet Microoptics by Two-Photon Grayscale Lithography" presents the design, fabrication, and optimization of complex microoptical components using a novel 3D printing method called two-photon grayscale lithography (2GL). Key points from the article include:

1. **Technology Overview**: The use of two-photon photopolymerization (2PP) has evolved since the 1990s to manufacture microoptical components. The authors demonstrate the creation of singlet and doublet microoptics using 2GL, which offers better shape accuracy compared to conventional 2PP.

2. **Fabrication Process**: Microoptics are printed using the Nanoscribe Quantum X system, employing liquid photoresist and ultra-short light pulses to harden the resist within a highly focused region called the voxel. The grayscale method allows for smoother, more accurate curved surfaces by modulating laser power during fabrication.

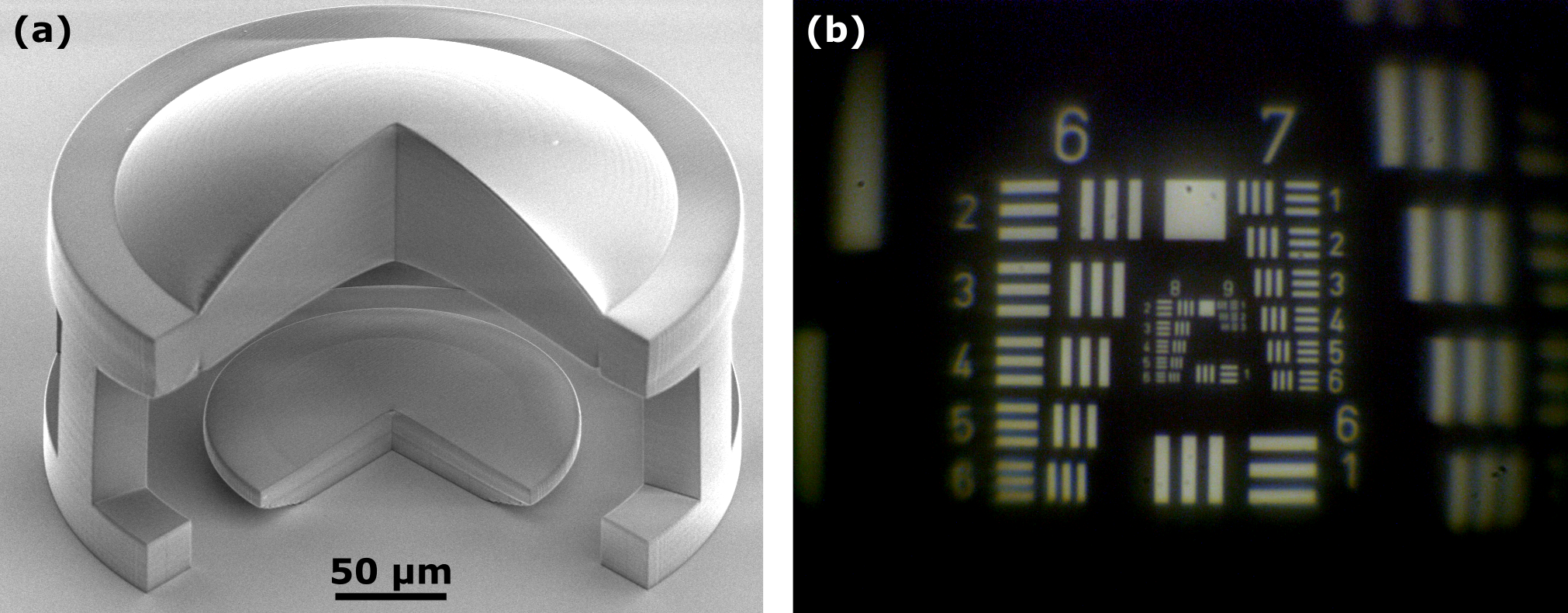

3. **Air-Spaced Doublet Design**: A doublet system with two aspherical lenses was designed using ZEMAX OpticsStudio software, optimized for optical imaging. This system features a diameter of 300 µm and a focal length of 275 µm, with smooth surfaces and high optical clarity achieved through confocal microscopy and an iterative design process.

4. **Performance and Testing**: The optical performance of the fabricated doublet was tested using a USAF 1951 resolution test chart, yielding a resolution of 645 lp/mm, with minimal barrel distortion and chromatic aberrations. The shape deviations were kept below 20 nm for the bottom lens and below 100 nm for the top lens after optimization.

5. **Conclusion and Future Applications**: The authors highlight the success of the 2GL technique in creating high-resolution, step-free microoptical components. The technology holds promise for future applications, including potential use in quantum technologies for photon emission coupling.

This paper illustrates the advancements in 3D microfabrication techniques, offering more precision and better performance for microoptical devices.

OMeda (Shanghai Omedasemi Co.,Ltd) was founded in 2021 by 3 doctors with more than 10 years of experience in nanpfabrication. It currently has 15 employees and has rich experience in nanofabrication (coating, lithography, etching, two-photon printing, bonding) and other processes. We support nanofabrication of 4/6/8-inch wafers.